Chilled Water Pump Details Cadbull

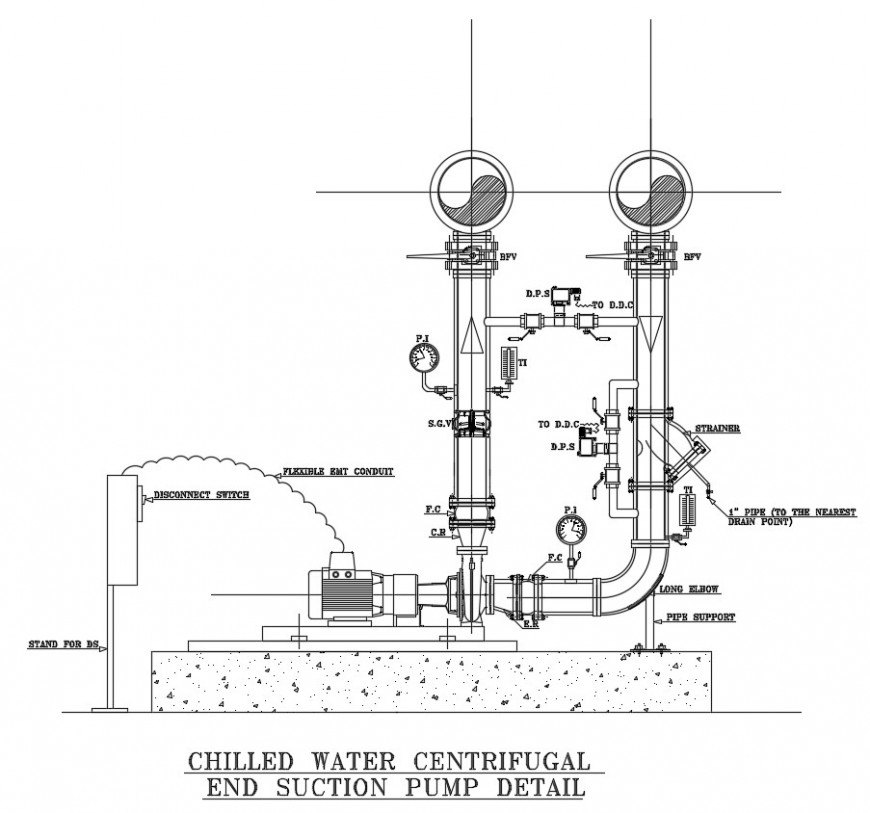

Chilled Water End Suction Pump Detail Autocad Software Cadbull Description. chilled water pump room section, plan and processing plumbing details that includes a detailed view of controller to valve details & wiring diagram, pipe and wire trenching, main isolation valve assembly control valve assembly with air vacuum relief valve, drain flush valve, dripper for palms and trees, drip line connection details, pvc to pe drip line take off and drip. 2d cad drawing of ugw tank. gas line detail drawing pr. chilled water end suction pump detail autocad software detailed with strture plan elevation of water pump suction plan with all long volt pipes and long elbow panel elevation with flexible ent conduct and disconnect strainer elevation shown in drawing with all described elevation.

-Chilled-Water-Pump-Machine-Working-Design-CAD-File--Sat-Nov-2019-09-07-41.jpg)

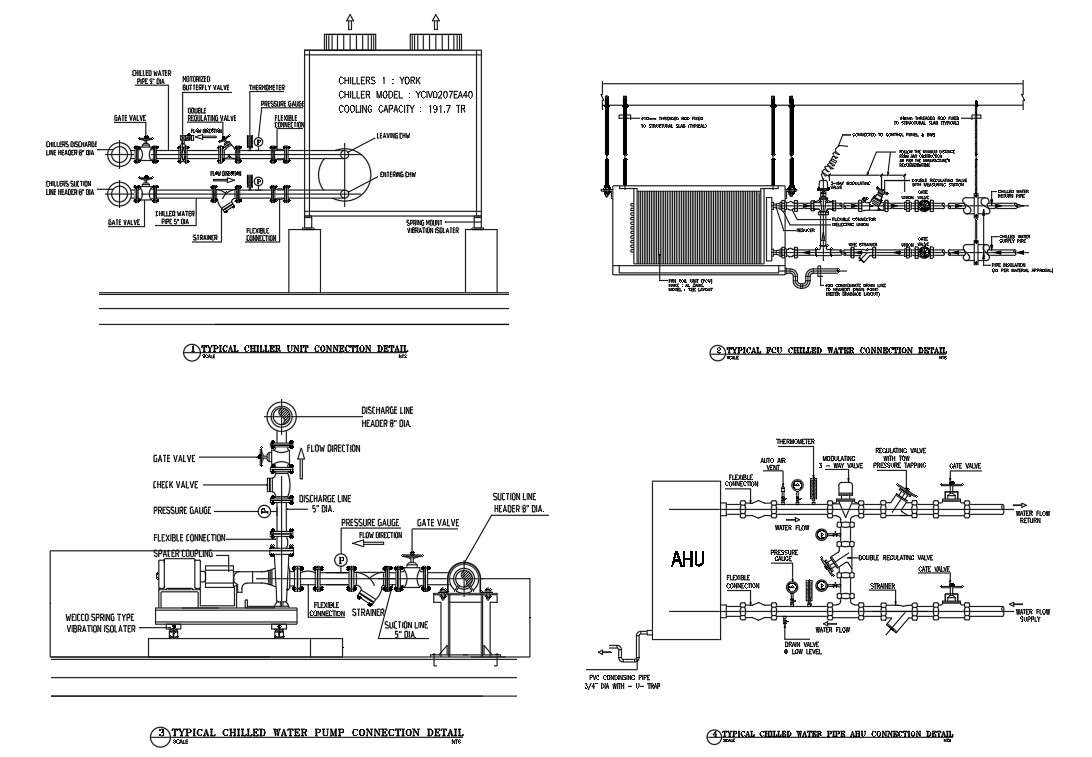

Chwp Chilled Water Pump Machine Working Design Cad File Cadbull 6.7 pump speed. the pump speeds available for chilled water pumps include 1,200, 1,800 and 3,600 rpm. when you choose the pump speed, you must first ensure that the pump manufacturer has that speed available. lower pump speeds are preferred because the increased number of rotations will cause increased wear and tear. Description. all sided section and plumbing structure drawing details of chilled water pump room that includes a detailed view of controller to valve details & wiring diagram, pipe and wire trenching, main isolation valve assembly control valve assembly with air vacuum relief valve, drain flush valve, dripper for palms and trees, drip line connection details, pvc to pe drip line take off and. However, 45 degree pipe elbows occupy more spaces. when you’re designing a chilled water pump connection, you may allow a 300mm short piece of pipe in between each valve. besides, put a 300mm short piece of pipe before a 90 degree elbow for better flow. if you really have no space, use 150mm instead of 300mm. In a chilled water system to remove heat from zone or process loads. this system comprises one or more chillers, cooling tower(s), condenser water pumps, chilled water pumps, and load terminals served by control valves. fixed or variable speed compressors provide cooling, while flow rates are optimized for a combination of efficiency and cost.

All Sided Section And Plumbing Structure Drawing Details Of Chilled However, 45 degree pipe elbows occupy more spaces. when you’re designing a chilled water pump connection, you may allow a 300mm short piece of pipe in between each valve. besides, put a 300mm short piece of pipe before a 90 degree elbow for better flow. if you really have no space, use 150mm instead of 300mm. In a chilled water system to remove heat from zone or process loads. this system comprises one or more chillers, cooling tower(s), condenser water pumps, chilled water pumps, and load terminals served by control valves. fixed or variable speed compressors provide cooling, while flow rates are optimized for a combination of efficiency and cost. Chilled water schematic and condenser water schematic, how to read and understand the engineering drawings with real world examples, illustrations, animations and video tutorial. covering chillers, pump sets, ahus, risers, primary and secondary systems, cooling towers and bypass lines. A chilled water system can be separated into water cooled and air cooled. water cooled chilled water systems are larger and more efficient than air cooled chilled water systems. a typical water cooled chilled water system consists of 4 major components as below: chiller. cooling tower.

Chiller Water Pump Design Cad Drawing Cadbull Chilled water schematic and condenser water schematic, how to read and understand the engineering drawings with real world examples, illustrations, animations and video tutorial. covering chillers, pump sets, ahus, risers, primary and secondary systems, cooling towers and bypass lines. A chilled water system can be separated into water cooled and air cooled. water cooled chilled water systems are larger and more efficient than air cooled chilled water systems. a typical water cooled chilled water system consists of 4 major components as below: chiller. cooling tower.

Chilled Water Pump Details Cadbull Vrogue Co

Comments are closed.