Cirrus Go Lean Six Sigma

Cirrus Go Lean Six Sigma Cirrus, the specialist artwork management service for healthcare packaging, has just successfully completed yellow belt training for all its employees as part of a go lean six sigma programme. lean six sigma is a combination of two complementary process improvement methods: lean and six sigma. Improve your company’s efficiency with the best lean six sigma training join over 6,200 companies that partner with glss to train their teams and deliver measurable improvements in every job function and industry. try it free book a demo here are 4 reasons why glss is the best lean six sigma training solution for your […].

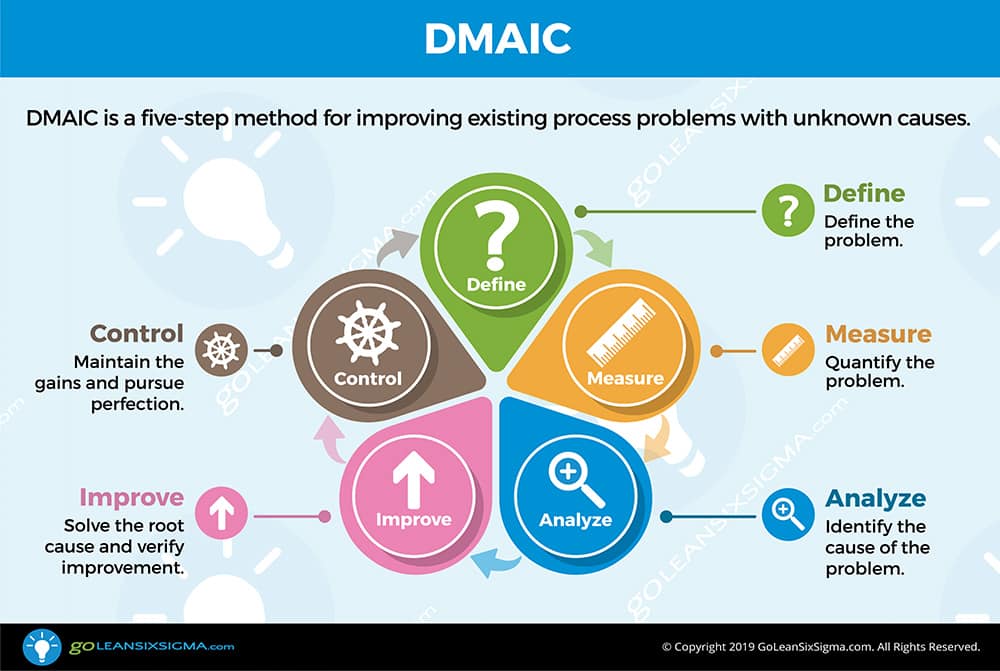

Lean Six Sigma Methodologies Dmaic is the problem solving approach that drives lean six sigma. it’s a five phase method—define, measure, analyze, improve and control—for improving existing process problems with unknown causes. dmaic is based on the scientific method and it’s pronounced “duh may ik.”. originally published on august 24th, 2017, this article was. Lean six sigma (lss) is a project management methodology. it equips organizations across the spectrum—from fortune 500 giants to government bodies, nonprofits, and small to medium sized enterprises—with the tools to reduce costs, boost productivity, and deliver unparalleled customer value. six sigma is a combination of two popular process. On site, virtual or off site. the lean six belt boot camp is 120 hours of experienced, in person and interactive training. become a leader in facilitating lean in your organization and building your career path in continuous process improvement skills. change and continuous improvement is a process. it begins with having the necessary skills. It is easy and informative for our green belt candidates without taking as much time as other packages. the belts seem to like the bahama bistro simulation that is given throughout training. we are very happy with the service and support of go lean six sigma as well. date of experience: july 24, 2020. useful.

Lean Six Sigma Process Improvement Goleansixsigma On site, virtual or off site. the lean six belt boot camp is 120 hours of experienced, in person and interactive training. become a leader in facilitating lean in your organization and building your career path in continuous process improvement skills. change and continuous improvement is a process. it begins with having the necessary skills. It is easy and informative for our green belt candidates without taking as much time as other packages. the belts seem to like the bahama bistro simulation that is given throughout training. we are very happy with the service and support of go lean six sigma as well. date of experience: july 24, 2020. useful. The primary difference between lean and six sigma is that lean is less focused entirely on manufacturing, but often shapes every facet of a business. lean six sigma combines these two approaches, which creates a powerful toolkit for addressing waste reduction. as companies seek to understand where they may have wasteful practices in place, the. 4. improve. in this phase, the team develops and implements process improvements by using the information gathered in the previous phases. the team may use lean tools to reduce waste, improve flow and make the process more efficient. the team may also use six sigma tools to reduce variation and improve quality. 5.

Go Lean Six Sigma Secrets From Waste To Wow The primary difference between lean and six sigma is that lean is less focused entirely on manufacturing, but often shapes every facet of a business. lean six sigma combines these two approaches, which creates a powerful toolkit for addressing waste reduction. as companies seek to understand where they may have wasteful practices in place, the. 4. improve. in this phase, the team develops and implements process improvements by using the information gathered in the previous phases. the team may use lean tools to reduce waste, improve flow and make the process more efficient. the team may also use six sigma tools to reduce variation and improve quality. 5.

Comments are closed.