Compressed Air Testing Why How To Test Industrial Air Gas

Compressed Air Testing Why How To Test Industrial Air Gas A compressed air test is a standardized procedure used to ascertain the quality of the produced air. compressed air testing determines that the compressed air being supplied to industrial processes is free of impurities. the contaminants routinely tested for are water, suspended particles, and oil residue generated from three major sources:. 5. oil aerosol testing. this method involves the use of high efficiency membranes. oil from compressed air samples is dissolved on these membranes by a solvent and subsequently analyzed by infrared spectrometry. oil aerosol testing can be used to analyze samples where higher levels of contamination are anticipated. 6.

How Compressed Air Testing Kits Work Tri Air Testing Oil (liquid, vapor and aerosol) microorganisms. the international standard iso 8573 1:2010 is a compressed air quality specification that addresses these very same specific contaminants by providing a range of purity classes for particles, water and oil. it does not include classes for gases or microorganisms. Contact us to start testing. get in touch with us – we'll answer all of your compressed air testing questions. use the form below or call us at 800 247 1024. iso 8573 compressed air testing provides limits for particles, water, and oil. we offer iso 8573 1 and iso 8573 7 compressed air testing options. Employing a standard for compressed air testing. iso 8573 consists of 9 parts in which iso 8573 1 is most frequently cited. parts 2 through 9 provide analytical techniques and sampling methods. many air compressor and filter manufacturers cite iso 8573 1:2010 purity classes to describe the quality of air that can be produced with their products. Oil in compressed air gas systems can also affect air flow rate and capacity. methods of testing for oil include: oil aerosol testing: membranes are used to collect oil from compressed air gas, which is then dissolved and further analyzed with a spectrometer. oil vapor testing: in this method, a gas chromatography sampling probe tests an.

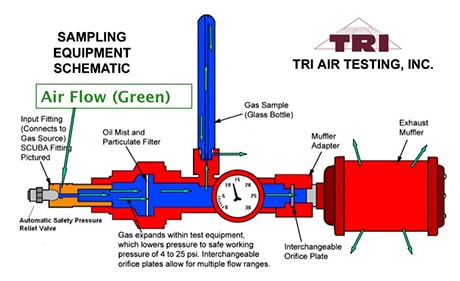

How To Test Compressed Air Quality Technical Safety Services Employing a standard for compressed air testing. iso 8573 consists of 9 parts in which iso 8573 1 is most frequently cited. parts 2 through 9 provide analytical techniques and sampling methods. many air compressor and filter manufacturers cite iso 8573 1:2010 purity classes to describe the quality of air that can be produced with their products. Oil in compressed air gas systems can also affect air flow rate and capacity. methods of testing for oil include: oil aerosol testing: membranes are used to collect oil from compressed air gas, which is then dissolved and further analyzed with a spectrometer. oil vapor testing: in this method, a gas chromatography sampling probe tests an. The oil check 400 enables permanent, highly accurate measuring of the residual vapour oil content from 0.001 mg m3 to 2.5 mg m3. the minimum measured value of 0.001 mg m3 means that compressed air quality class 1 (iso 8573 1) can be monitored. this means that the entire measuring range can be monitored with the oil check 400. August 13, 2018 technical document td 08 rev 1. it is paramount that the air gas component and contaminate testing be performed with good field sampling and analytical methodology. this means using generally accepted practices that are relevant to operation and are capable of reproducible results. the international standards organization, iso.

Compressed Air Testing Why How To Test Industrial Air Gas The oil check 400 enables permanent, highly accurate measuring of the residual vapour oil content from 0.001 mg m3 to 2.5 mg m3. the minimum measured value of 0.001 mg m3 means that compressed air quality class 1 (iso 8573 1) can be monitored. this means that the entire measuring range can be monitored with the oil check 400. August 13, 2018 technical document td 08 rev 1. it is paramount that the air gas component and contaminate testing be performed with good field sampling and analytical methodology. this means using generally accepted practices that are relevant to operation and are capable of reproducible results. the international standards organization, iso.

Iso 8573 Compressed Air Testing Quick View Youtube

Comments are closed.