Cooling Tower Diagram A Go To Guide To Learn About Their Function

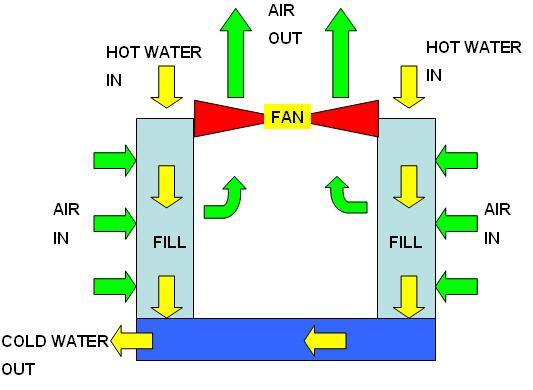

Cooling Tower Diagram A Go To Guide To Learn About Their Function There are some cooling tower basics you need to know to understand the cooling tower diagram better such as different parts and types of towers. cooling towers feature a system for distributing the air, a basin or liquid holding system, an outer structure or casing, a medium to help transfer the heat, and a fan for moving the air. A cooling tower flow diagram helps visualise the complex system of the tower and its components. the diagram illustrates the flow of water and air through the tower, as well as the different stages of the cooling process. the cooling tower flow diagram typically begins with the entry of hot water from the industrial process into the tower.

Cooling Tower Diagram A Go To Guide To Learn About Their Function The water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical "cooling tower fan". when the air and water come into the contact, a little amount of water dissipates, producing a cooling operation. and again the cold water is pumped back to the machine that incorporates heat or the. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. during this process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower.

Cooling Tower Diagram A Go To Guide To Learn About Their Function The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. during this process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower. Explore the intricacies of cooling tower parts and functions with our comprehensive guide. learn about the vital components that make up these essential elements of industrial processes. 1 303 462 2000 (usa). The cold air drawn in through the bottom hits the exchange surface, cooling down the hot water which then drops into the basin at the bottom of the cooling tower. this water is then funnelled back into the industrial system industrial process from where it came and the whole cycle begins again. it is estimated that around 2% of the water which.

Comments are closed.