Cooling Tower Piping Layout And Diagrams Constructandcommission

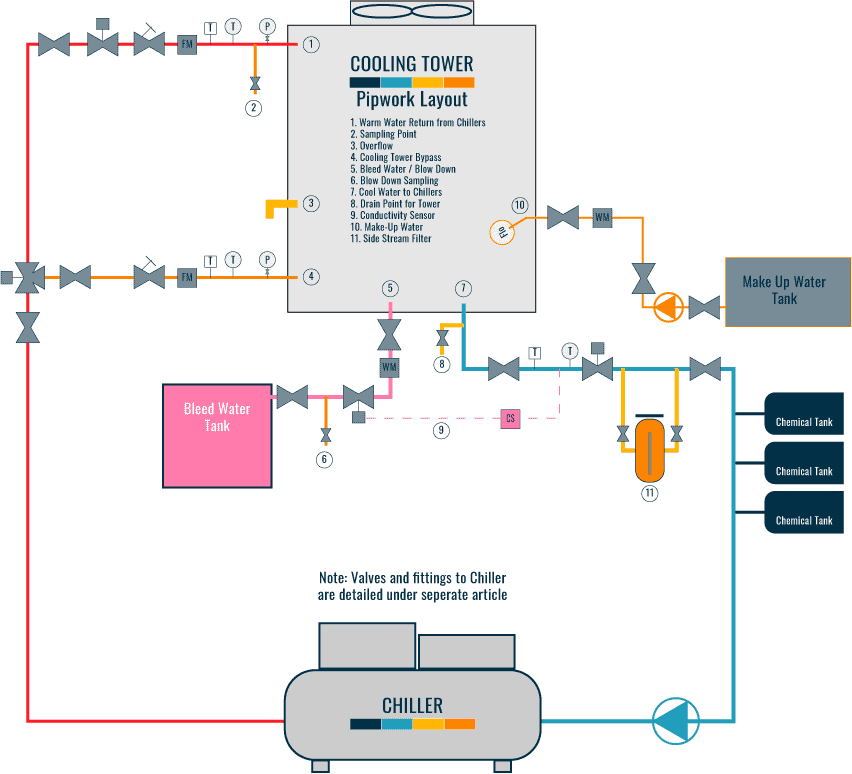

Cooling Tower Piping Layout And Diagrams Constructandcommission Cooling tower | piping layout and diagrams. to allow the cooling towers to operate correctly, in line with the design and efficiently, various systems will need to be connected to allow them to work. depending upon how the towers are installed will mean different configurations would be required. the pipework that is commonly connected to the. The cooling tower casing surrounds and encloses most of the cooling tower parts, such as the basin, the drift eliminators, and the fans. it also contains spray and water, allowing it to fall directly to the basin and not be carried off by the wind. the casing can be made from galvanized steel, stainless steel, or fiberglass.

Cooling Tower Piping Layout And Diagrams Constructandcommission 2. all doors can be fully opened to gain access to the cooling tower internal area. 3. check that there is enough space for the fill pack and fans to be removed and replaced. 4. if the cooling tower is mounted on a steel high platform, confirm that there is a safe manner to gain access, remove the parts and components. The cooling tower circuit differs slightly from the basic “open” circuit in that the discharge piping is connected directly to a distribution basin. some towers are furnished with a distribution manifold with nozzles which require additional pressure. figure 3 typical “open” tower piping. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Product: cooling towers – free cooling operation date: april 16, 2010 table of contents section page i. introduction background 2 ii. system design considerations: cooling tower selection 5 unit layout 6 cooling tower piping 7 cooling tower accessories 8 iii. capacity control methods 10.

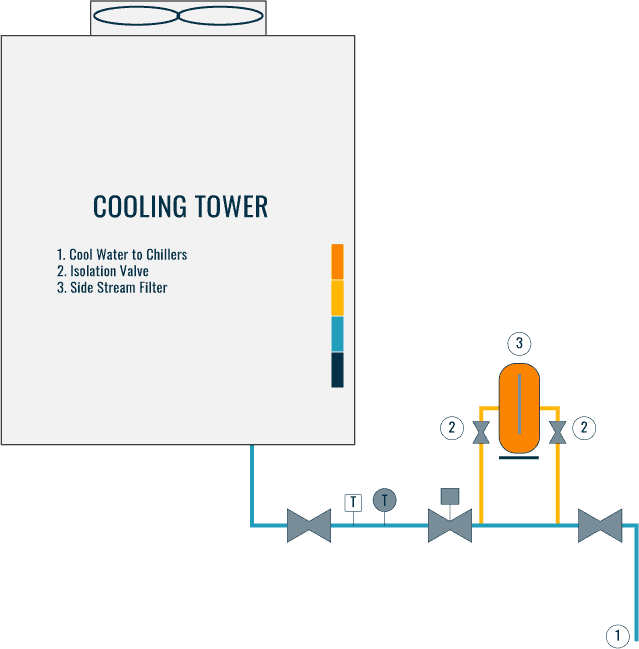

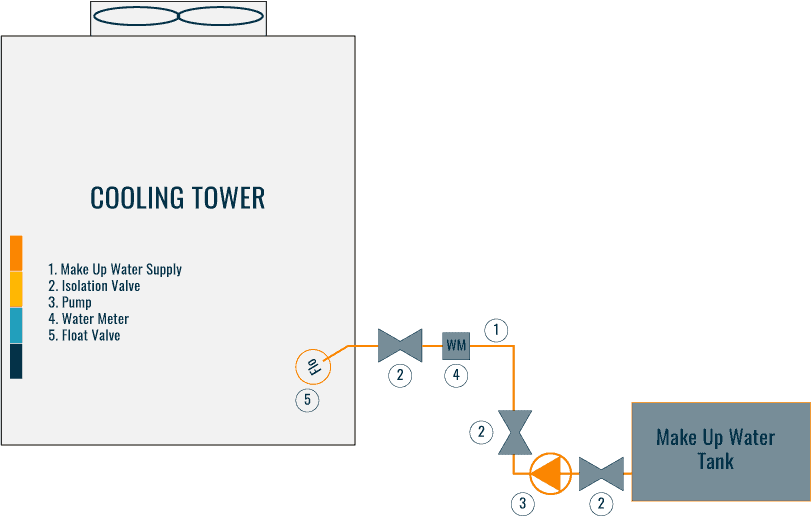

Cooling Tower Piping Layout And Diagrams Constructandcommission Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Product: cooling towers – free cooling operation date: april 16, 2010 table of contents section page i. introduction background 2 ii. system design considerations: cooling tower selection 5 unit layout 6 cooling tower piping 7 cooling tower accessories 8 iii. capacity control methods 10. Understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and controls will improve heat transfer and avoid problems such as air. Cooling tower is the most common equipment facility in any refinery, petrochemical and petroleum plants. cooling towers are heat exchangers that are used to dissipate large heat loads to the atmosphere generated in the process plants. this design guide provides the guidelines for the designing of the equipment layout and piping arrangement for.

Cooling Tower Piping Layout And Diagrams Constructandcommission Understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and controls will improve heat transfer and avoid problems such as air. Cooling tower is the most common equipment facility in any refinery, petrochemical and petroleum plants. cooling towers are heat exchangers that are used to dissipate large heat loads to the atmosphere generated in the process plants. this design guide provides the guidelines for the designing of the equipment layout and piping arrangement for.

Comments are closed.