D C Armature Winding Lap Winding Wave Winding

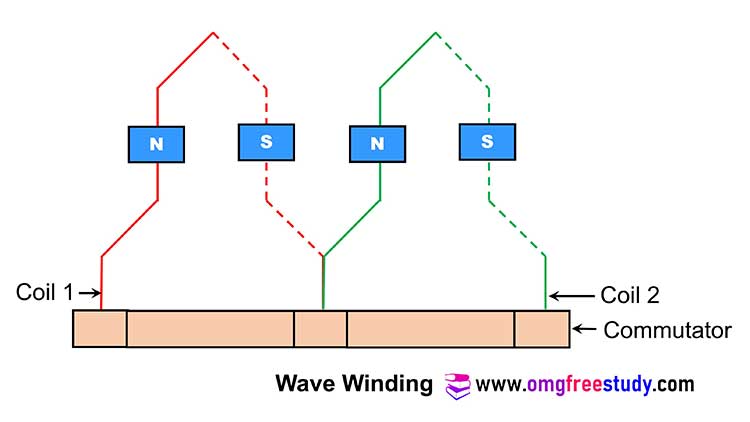

Armature Winding Lap Winding And Wave Winding Of Dc Machine Wave winding definition: a wave winding is defined as a type of armature winding where the end of one coil connects to the start of another, creating a wave like pattern. simplex wave winding: simplex wave winding has odd back pitch and front pitch that are nearly equal and suitable for high voltage, low current machines. The main difference between lap and wave winding is the manner of connecting the armature winding coil end to the commutator segment. in lap winding the top and bottom coil ends are connected to adjacent commutator segment whereas in wave winding, they are bent in opposite direction and connected to commutator segments which are approximately two pole pitches apart.

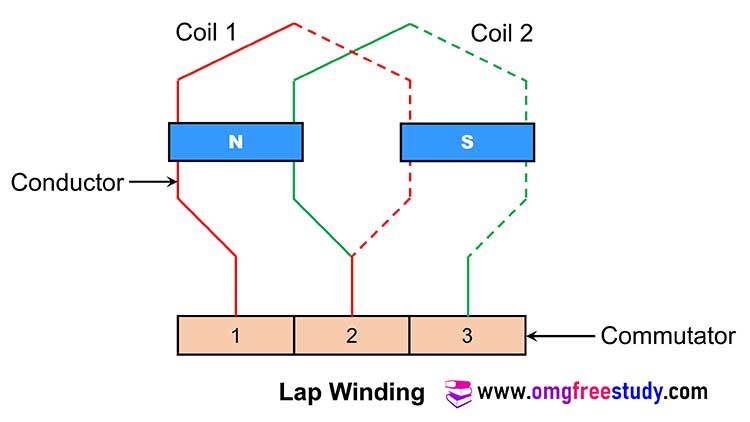

Lap Winding Y p = pole pitch. y r = resultant pitch. then, the back and front pitches are of opposite sign and they cannot be equal. y b = y f ± 2m. m = multiplicity of the winding. m = 1 for simplex lap winding. m = 2 for duplex lap winding. when, y b > y f, it is called progressive winding. Lap winding; wave winding. lap winding. figure 2: lap winding. in lap winding, the start and finish ends of the coil of an armature winding terminate on two adjacent commutator segments. when the start end terminates on a commutator segment and the finish end terminates on the next forward segment, it is called a progressive lap winding. 1. simplex lap winding: in simplex lap winding, the terminating end of one coil is joined to the commutator segment and the starting end of the next coil is placed under the same pole. also, the number of parallel paths is similar to the number of poles of the windings. 2. duplex winding: in duplex winding the number of parallel paths between. The armature winding is mainly classified into two types, i.e., the lap winding and the wave winding. one of the major difference between them is that in a lap winding the end of each coil are connected to the adjacent segment whereas in the wave winding the end of armature coil connected to commutator segment at a distance apart.

Armature Winding Lap Winding And Wave Winding Of Dc Machine 1. simplex lap winding: in simplex lap winding, the terminating end of one coil is joined to the commutator segment and the starting end of the next coil is placed under the same pole. also, the number of parallel paths is similar to the number of poles of the windings. 2. duplex winding: in duplex winding the number of parallel paths between. The armature winding is mainly classified into two types, i.e., the lap winding and the wave winding. one of the major difference between them is that in a lap winding the end of each coil are connected to the adjacent segment whereas in the wave winding the end of armature coil connected to commutator segment at a distance apart. The wave windings are used in small machines, since in the case of small machines the current carrying capacity of armature conductors is not critical. lap winding. in lap winding, the armature coils are connected in series through the commutator segments in such a way that the armature winding is divided into as many parallel paths as the. Lap winding figure from principles of electric machines and power electronics, 2nd edition, p.c. sen, john wiley and sons, 1997. figure represents an unrolled lap winding of a dc armature, along with the commutator segments (bars) and stationary brushes. coils are added in series until the end of the last coil joins the beginning of the first coil.

Comments are closed.