Disposable Single Use Technology In Fermentation Technology

Disposable Single Use Technology In Fermentation Technology Youtube When it comes to cost, the picture is more complex. the costs for consumables, such as disposable fermentor bags, were higher in the single use scenarios. this pushed up single use costs per batch 29% higher than stainless steel in the single product facility, and 25% higher in the multi product facility. Designed specifically for microbial fermentation. the thermo scientific hyperforma single use fermentor (s.u.f.) is pioneering the single use technology market by delivering a unique and rigorous solution for microbial fermentation applications while offering the flexibility, ease of use, and efficiency found in single use systems.

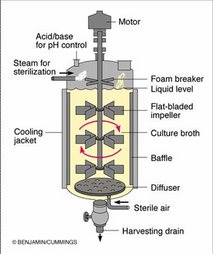

Pioneering Single Use Technology For Microbial Fermentation Ge Single use stirred tank fermentation technology has been available in smaller scale since 2007, but we are currently seeing an increased interest in adopting this technology also for pilot to large scale processes. single use sensors are also on the rise, including metabolite, cell mass, and near infrared sensors. Biopharma process online1. some reasons process manufacturers are switching to single use equipment include: eliminate cleaning requirements. decrease the risk of cross contamination. reduce capital investment in facilities and equipment. shorten the time it takes to get a facility up and running. Recent collaborations between leading filtration, container closure, mixing and fermentation cell culture suppliers has resulted in fully integrated single use disposable bioprocessing platforms and systems (sus.) implementing these sus into legacy and new processes requires examining many process parameters and cost benefit factors. And, specifically, for fermentation, single use technology eliminates cross contamination previously associated with o rings, gaskets, diaphragms and mechanical seals. the process piping from the stainless steel equivalent has been replaced by elastomeric tubing. no cleaning necessary, just discard similar to other process waste.

Fermentation Technology Fermentation Introduction Recent collaborations between leading filtration, container closure, mixing and fermentation cell culture suppliers has resulted in fully integrated single use disposable bioprocessing platforms and systems (sus.) implementing these sus into legacy and new processes requires examining many process parameters and cost benefit factors. And, specifically, for fermentation, single use technology eliminates cross contamination previously associated with o rings, gaskets, diaphragms and mechanical seals. the process piping from the stainless steel equivalent has been replaced by elastomeric tubing. no cleaning necessary, just discard similar to other process waste. The design challenges and demands for sensor applications suited for single use technology are summarized. finally, an overview of applications in the cultivation of mammalian, insect, and plant cell lines, for aerobic and anaerobic cultivation of bacteria, fungi, and yeast is presented as well as the application for phototrophic and. Today sartorius offers a wide variety of single use bioreactors which are ideal for mammalian cell culture, very demanding high cell density or microcarrier based processes. our single use bioreactors from 15 ml working volume with ambr ® 15 to biostat ® str 2,000 l have been developed to ensure easy and straightforward scale up and scale down.

Comments are closed.