Handbook The Ultimate Guide To Resin Molds 2024 Updated

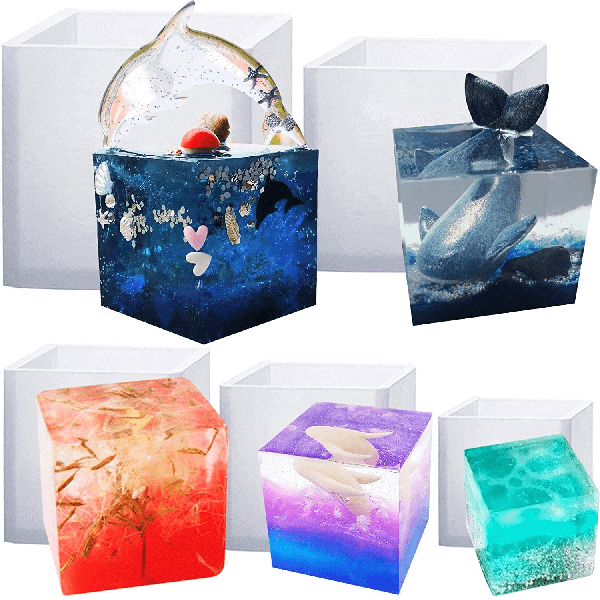

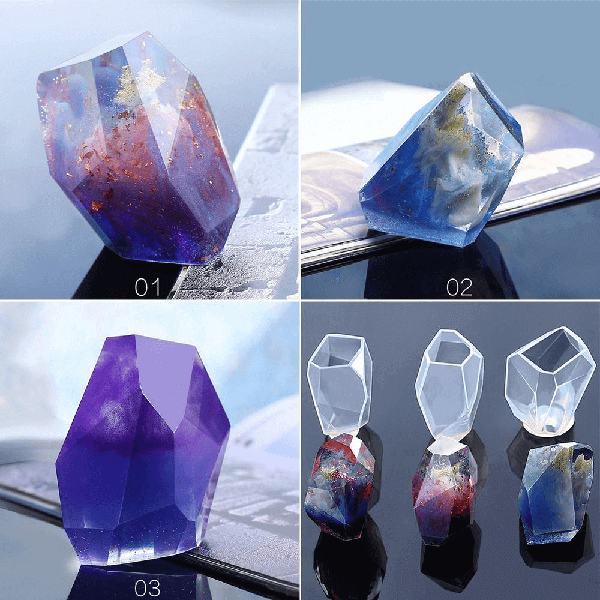

Handbook The Ultimate Guide To Resin Molds 2024 Updated Handbook: the ultimate guide to…. well, creativity plays a critical role in finding new approaches to making molds. among the unique inventions, resin molds emerged. one can use casing resin molds to make specific molds of the object you want to display. the process begins by pouring resin into molds for it replicate the mold’s actual shape. Step 1: gather your materials. start by gathering all the necessary materials. this includes the resin, a mold making material (like silicone), a mold box, a mixing cup, a stirring stick, and a release agent. ensure you have everything at hand before you start. step 1.

Handbook The Ultimate Guide To Resin Molds 2024 Updated This handbook will tell you everything. the ultimate guide to mold making 2024 updated. resin molds. washing machine. Step 1: making a prototype. start by creating a prototype of the shape you want your resin mold to be. you can use clay or any other material that's easy to shape. make sure your prototype is smooth and free of any imperfections, as these will transfer to your mold and ultimately to your resin art. previous. Step 1: clean the mold. start by thoroughly cleaning your mold. use a soft cloth to remove any dust or debris. ensure the mold is completely dry before proceeding. step 1. step 2. step 3. step 4. unleashing your creativity with resin art begins with mastering the art of mold preparation. Resin molds and silicone molds can be cleaned with a cosmetic brush or any other soft brushes. gently rub the brush on the dust and dried residue. it is easily available. you don’t need to buy a new brush as you can use any soft brush lying around. before starting a new resin project, make sure your resin molds are clean.

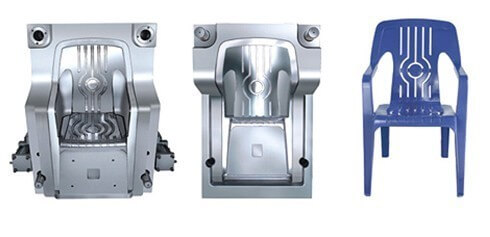

Handbook The Ultimate Guide To Resin Molds 2024 Updated Step 1: clean the mold. start by thoroughly cleaning your mold. use a soft cloth to remove any dust or debris. ensure the mold is completely dry before proceeding. step 1. step 2. step 3. step 4. unleashing your creativity with resin art begins with mastering the art of mold preparation. Resin molds and silicone molds can be cleaned with a cosmetic brush or any other soft brushes. gently rub the brush on the dust and dried residue. it is easily available. you don’t need to buy a new brush as you can use any soft brush lying around. before starting a new resin project, make sure your resin molds are clean. Molding or mold making is an elaborate process of making the cavity structure that conveys a negative or opposite impression of an original model. molds can be made of an inflexible or rigid material, for example, mortar or plastic resin or all the more generally, an adaptable material, for example, rubber. the material to use for molding is. Step 4. now, start slowly pouring the silicone into the mold, try to pour evenly and thinly holding the cup a little away from the mold. in the meantime, move your hand inside the shell, gently covering the empty space first. step 5.with attention, the silicon should stand for at least 12 hours to harden.

Handbook The Ultimate Guide To Mold Making 2024 Updated Molding or mold making is an elaborate process of making the cavity structure that conveys a negative or opposite impression of an original model. molds can be made of an inflexible or rigid material, for example, mortar or plastic resin or all the more generally, an adaptable material, for example, rubber. the material to use for molding is. Step 4. now, start slowly pouring the silicone into the mold, try to pour evenly and thinly holding the cup a little away from the mold. in the meantime, move your hand inside the shell, gently covering the empty space first. step 5.with attention, the silicon should stand for at least 12 hours to harden.

Handbook The Ultimate Guide To Mold Making 2024 Updated

Comments are closed.