How Does Mes Drive Manufacturing Excellence

How Does Mes Drive Manufacturing Excellence Datix Find out how epicor’s mes tools can make your manufacturing enterprise faster and leaner than ever. epicor mes advantages precise, real time data . mes is tightly integrated with the epicor job management, scheduling, quality assurance and advanced material management modules. Mes is a powerful tool for manufacturers, enabling them to optimize their operations, enhance product quality, reduce waste, and ensure compliance with industry standards and regulations. it acts as the bridge between shop floor systems and enterprise level management, enabling a seamless flow of information and more informed decision making.

Manufacturing Executive System Mes And How Can It Benefit Me Cloud In manufacturing operations management, an mes serves as a bridge between the planning and control systems of an enterprise, such as an enterprise resource planning (erp) system, and the actual manufacturing operations. the primary purpose of an mes is to track and document the transformation of raw materials into finished products in real time. Mes serves as a catalyst for continual process improvement, enabling organizations to implement lean practices, drive operational excellence, and cultivate a culture of continuous improvement. through data driven insights and performance metrics, organizations can identify areas for optimization, implement corrective measures, and foster a. The precision and real time feedback mes driven systems provide enable manufacturers to utilize raw materials more efficiently, thus minimizing waste and enhancing sustainability efforts. this efficient use of resources not only cuts costs but also improves the overall environmental footprint of the manufacturing process. And we know that you need intelligent, individualized, scalable solutions to keep up – and get ahead. an mes gives you the ability to manage workflows and generate valuable production data that can make your operations more efficient, productive and responsive. your team can harness that power to not only resolve production issues in the.

Mes Manufacturing Execution System Explained Vrogue Co The precision and real time feedback mes driven systems provide enable manufacturers to utilize raw materials more efficiently, thus minimizing waste and enhancing sustainability efforts. this efficient use of resources not only cuts costs but also improves the overall environmental footprint of the manufacturing process. And we know that you need intelligent, individualized, scalable solutions to keep up – and get ahead. an mes gives you the ability to manage workflows and generate valuable production data that can make your operations more efficient, productive and responsive. your team can harness that power to not only resolve production issues in the. And effectively. in manufacturing, those functions are typically addressed by manufacturing execution systems (mes). interestingly, many of the same factors that drive manufacturing efficiency and process improvement programs like lean manufacturing (a method of improving production by removing wasted activities) also support agility. becoming. The data collected by mes becomes instrumental in crafting ai models and constructing digital twins, facilitating simulation and analysis, offering a clearer understanding and improved management of the manufacturing processes. obviously, mes is envisioned as the foundational cornerstone for transitioning to industry 4.0.

What Is Manufacturing Execution System Mes And effectively. in manufacturing, those functions are typically addressed by manufacturing execution systems (mes). interestingly, many of the same factors that drive manufacturing efficiency and process improvement programs like lean manufacturing (a method of improving production by removing wasted activities) also support agility. becoming. The data collected by mes becomes instrumental in crafting ai models and constructing digital twins, facilitating simulation and analysis, offering a clearer understanding and improved management of the manufacturing processes. obviously, mes is envisioned as the foundational cornerstone for transitioning to industry 4.0.

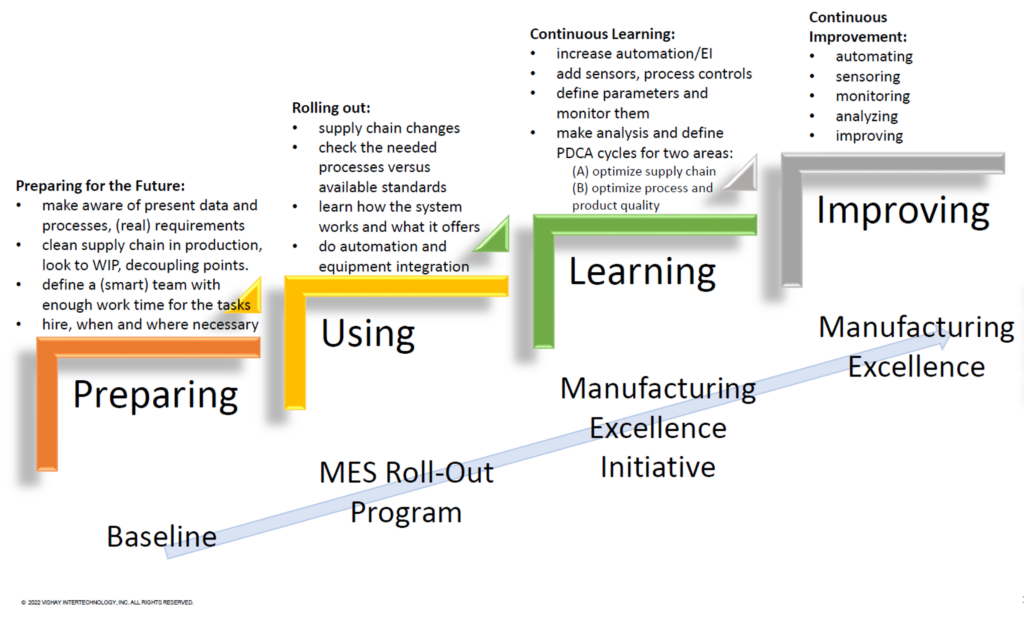

Manufacturing Excellence With One Mes

Comments are closed.