How Foam Compression Works

How Foam Compression Works Youtube When evaluating a foam product for use in a comfort application, perhaps the most useful testing value for determining its usability is compression strength. this value rates a foam’s feel and firmness by testing how it yields to or supports applied weight. these values are the easiest way to categorize materials, making the selection of a. Hey guys, thanks for watching! this video is for anyone that is confused about what foam firmness or compression to get. it can seem confusing but we're here.

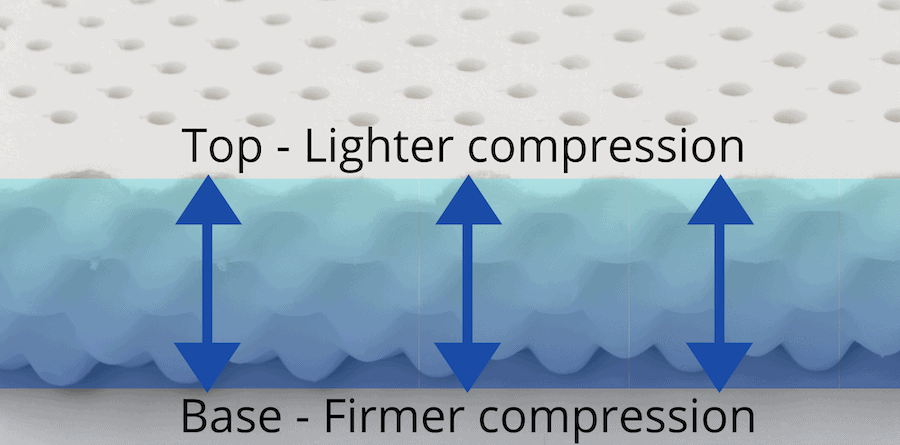

What Is Latex Foam Uses Pros And Cons Comparisons Guide вђ Foamhow Compression set, sometimes called c set, is an indicator of how a material behaves under certain conditions. the compression set test for foams and sponges include a 50% compression at various temperatures. room temperature 23°c, intermediate 70°c, and high (100°c for silicone). since heat is an “accelerator” of compression set, an. The compression resistance of foam is measured in pounds per square inch (psi), and the higher the psi, the better the foam’s ability to resist compression. tensile strength for foam products, tensile strength is an important property as it affects the foam’s ability to retain its shape and resist tearing or puncturing. Eva foam is known for its resilience and durability, but it can undergo compression set under sustained and continuous forces. this guide explores the intricacies of eva foam compression set, its causes, measuring techniques, and methods for mitigating it. by understanding compression set, manufacturers and users can optimize eva foam performance and ensure its long term integrity. Firmness is how soft the foam is, rated on a scale between 10 and 60 or more. whereas density denotes the weight of the foam – usually between 1lb and 3lb in weight but can go up to 15lb. density is an indicator of quality and longevity. when selecting foam, aspects such as outdoor or indoor foam, the proper use, and fire retardancy.

Foam Compression Data A Foam At Different Stages Of Compression For Eva foam is known for its resilience and durability, but it can undergo compression set under sustained and continuous forces. this guide explores the intricacies of eva foam compression set, its causes, measuring techniques, and methods for mitigating it. by understanding compression set, manufacturers and users can optimize eva foam performance and ensure its long term integrity. Firmness is how soft the foam is, rated on a scale between 10 and 60 or more. whereas density denotes the weight of the foam – usually between 1lb and 3lb in weight but can go up to 15lb. density is an indicator of quality and longevity. when selecting foam, aspects such as outdoor or indoor foam, the proper use, and fire retardancy. There are many varieties of foam strength testing, but the primary one is the 25 percent compression test. this is the test being referred to anytime foam is stated to have an ild value. the most integral aspect of this test is ensuring that the foam sample sizes are always identical in dimensions: 4 inches thick, 15 inches wide and 15 inches long. What works well as a replacement is a 3 4″ layer (or 1″ if you can get it) of very high density volara foam which we spray glue to the base plywood and then add 2″ of high density 2.5lb 55lb compression white foam as the topper. the trouble is a lot of people offer “high density” when it really isn’t.

Compression Of Metallic Foam Youtube There are many varieties of foam strength testing, but the primary one is the 25 percent compression test. this is the test being referred to anytime foam is stated to have an ild value. the most integral aspect of this test is ensuring that the foam sample sizes are always identical in dimensions: 4 inches thick, 15 inches wide and 15 inches long. What works well as a replacement is a 3 4″ layer (or 1″ if you can get it) of very high density volara foam which we spray glue to the base plywood and then add 2″ of high density 2.5lb 55lb compression white foam as the topper. the trouble is a lot of people offer “high density” when it really isn’t.

Comments are closed.