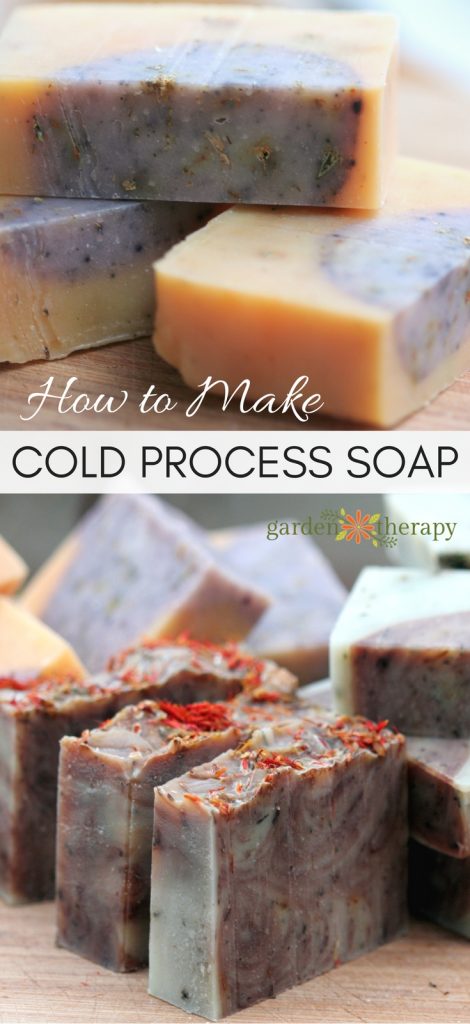

How To Make Soap From Scratch Using The Cold Process Method

Beginner Cold Process Soap Recipe How To Make Lye Soap Cold P Ladle about 1 2 to 1 cup of the soap mixture into a measuring cup. add the colorant to that bit of soap. hold the measuring cup several inches above the pot and slowly pour the colored soap into one corner of the soap pot. using a rubber spatula, swirl the colored soap through the pot. Then, pour the liquid oils in, too. when both the pot of oils and the lye solution are about 100 ° f (38 ° c), gently pour the lye solution into the oils. using a stick blender held under the liquid’s surface, alternate stirring and pulsing the liquid. when stirring, the stick blender should be off.

The Joy Of Cold Process Soap Making With Free Recipe Eccentricities 9. blend until trace. using a stick blender (also called immersion blender), blend the soap in short bursts of a few seconds at a time, stirring by hand with the motor off in between times. don’t run the stick blender continuously or you may burn out the motor and your soap will thicken up too quickly. You make soap from scratch by blending together: a liquid: water, goat’s milk, beer, etc. oils or fats: coconut oil, olive oil, tallow, etc. a caustic: sodium hydroxide (aka lye) for solid bar soap, potassium hydroxide (aka potash) for liquid soap. the lye is dissolved in the liquid first, and then is blended with the oils to create soap. Step 2. place the container for mixing your lye on the scale, press tare, and make sure it says 0. next measure the water you need 10.26 oz of filtered water. then carefully spoon the 4.54 oz of sodium hydroxide into the water until the scale reads 14.84 oz. set this glass container aside to cool. Pour the thickened soap mixture into your mold. tap the mold gently to eliminate any air pockets. then cover the soap with a towel to insulate and encourage the saponification process. in about 24 to 48 hours, your soap should be set enough to remove from the mold, but not quite ready for use yet.

Cold Process All Natural Handmade Soap Step 2. place the container for mixing your lye on the scale, press tare, and make sure it says 0. next measure the water you need 10.26 oz of filtered water. then carefully spoon the 4.54 oz of sodium hydroxide into the water until the scale reads 14.84 oz. set this glass container aside to cool. Pour the thickened soap mixture into your mold. tap the mold gently to eliminate any air pockets. then cover the soap with a towel to insulate and encourage the saponification process. in about 24 to 48 hours, your soap should be set enough to remove from the mold, but not quite ready for use yet. Now, slowly, pour the lye into the water, using a plastic spatula to stir until dissolved. the water will start to heat when it reacts with the lye (caustic soda sodium hydroxide), it will need to cool until it reaches the required temperature (see specific recipe). 310 grams distilled water, 145 grams soapmaking lye. Melt with a double boiler until up to 100 degrees fahrenheit. pour the lye solution into the container of oils. stir until trace is reached. (trace refers to the point when the oils and lye solution have emulsified. at this stage, there should be no streaks of oil, and the soap will have the consistency of batter.).

Natural Soap Making For Beginners The Cold Process Soap Making о Now, slowly, pour the lye into the water, using a plastic spatula to stir until dissolved. the water will start to heat when it reacts with the lye (caustic soda sodium hydroxide), it will need to cool until it reaches the required temperature (see specific recipe). 310 grams distilled water, 145 grams soapmaking lye. Melt with a double boiler until up to 100 degrees fahrenheit. pour the lye solution into the container of oils. stir until trace is reached. (trace refers to the point when the oils and lye solution have emulsified. at this stage, there should be no streaks of oil, and the soap will have the consistency of batter.).

How To Make Cold Process Soap From Scratch вђ Artofit

Comments are closed.