Mihow2 Baldor Ways To Minimize Damaging Shaft Currents

Mihow2 Baldor Ways To Minimize Damaging Shaft Currents Youtube Baldor electric outlines the ways to minimize the potential for damaging shaft currents found in motors run on adjustable speed drives. proper grounding, th. Baldor electric outlines the ways to minimize the potential for damaging shaft currents found in motors run on adjustable speed drives. proper grounding, the use of a shaft grounding brush and shaft grounding rings are just a few examples found in this short video.

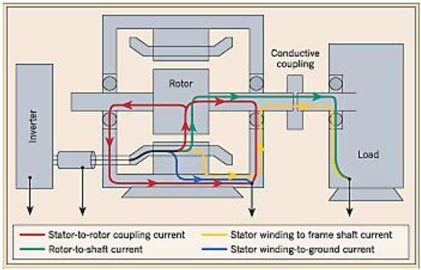

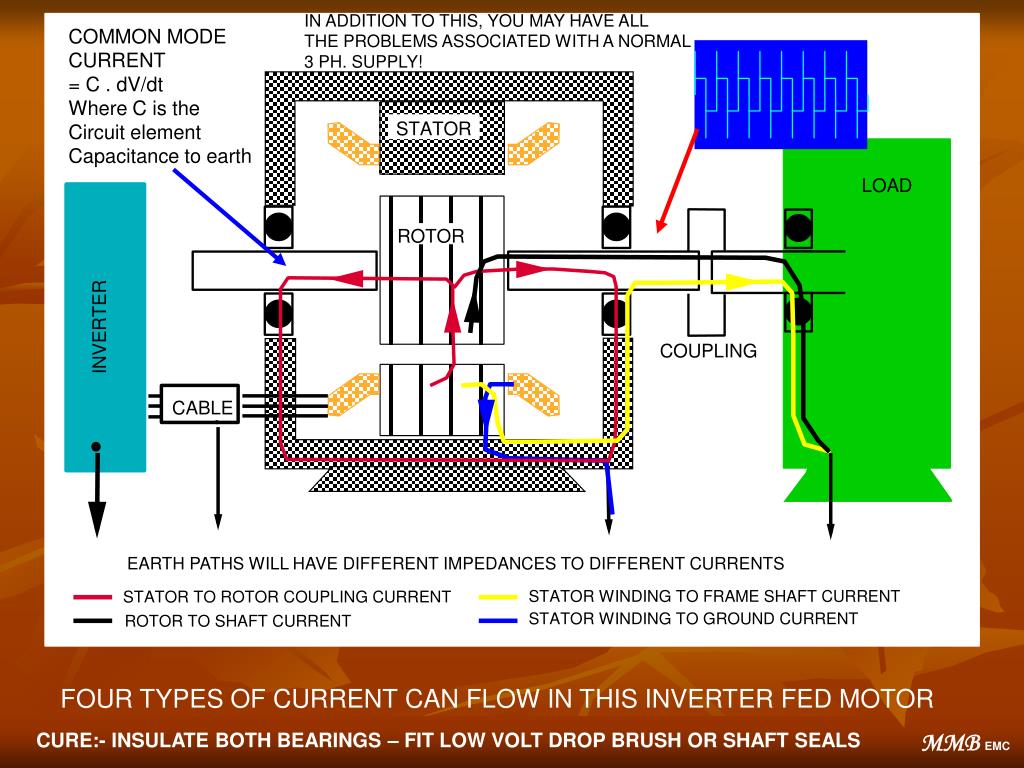

Learn About Shaft Currents Aka Electrically Induced Bearing Damage Mihow2 baldor troubleshooting elastomeric couplings. 2,989 views. mihow2 baldor ways to minimize damaging shaft currents. 2,677 views. 4:11. tom's toolbox. Generally endto end shaft voltage should be less than 0.5 v. normally, voltage levels below this will not cause harmful bearing currents. engineers can measure the shaft voltage with any. John malinowski of baldor electric in fort smith, ark., makes a similar point: we know a lot more about this phenomenon [stray shaft currents] today than in the past and can reduce its occurrence as long as correct vfd installation, setup and wiring practices are followed. obviously, there may be rare occasions where the fluting still occurs. The key to mitigating these currents is to provide low impedance ground connections or alternate conductive paths to ensure the current is channeled away from the bearings. (2) image 4a (top). common mode voltage for three phase sinewave voltages. image 4b (bottom). common mode voltage for three phase pwm voltages.

Ppt Shaft Current Powerpoint Presentation Free Download Id 1302109 John malinowski of baldor electric in fort smith, ark., makes a similar point: we know a lot more about this phenomenon [stray shaft currents] today than in the past and can reduce its occurrence as long as correct vfd installation, setup and wiring practices are followed. obviously, there may be rare occasions where the fluting still occurs. The key to mitigating these currents is to provide low impedance ground connections or alternate conductive paths to ensure the current is channeled away from the bearings. (2) image 4a (top). common mode voltage for three phase sinewave voltages. image 4b (bottom). common mode voltage for three phase pwm voltages. Baldor’s super e electric motor series comes with the baldor shaft grounding brush, which is designed to divert shaft currents away from the motor bearings and reducing wear and tear. stock ratings available include 1 through 50 hp in totally enclosed fan cooled (tefc) or open drip proof (odp) foot mounted designs along with 1 2 through 5 hp. Installing shaft grounding rings, determining common problems, using voltage testers, and vfd training videos. mihow2 – ways to minimize shaft currents by.

Comments are closed.