Oee Calculation Overall Equipment Effectiveness

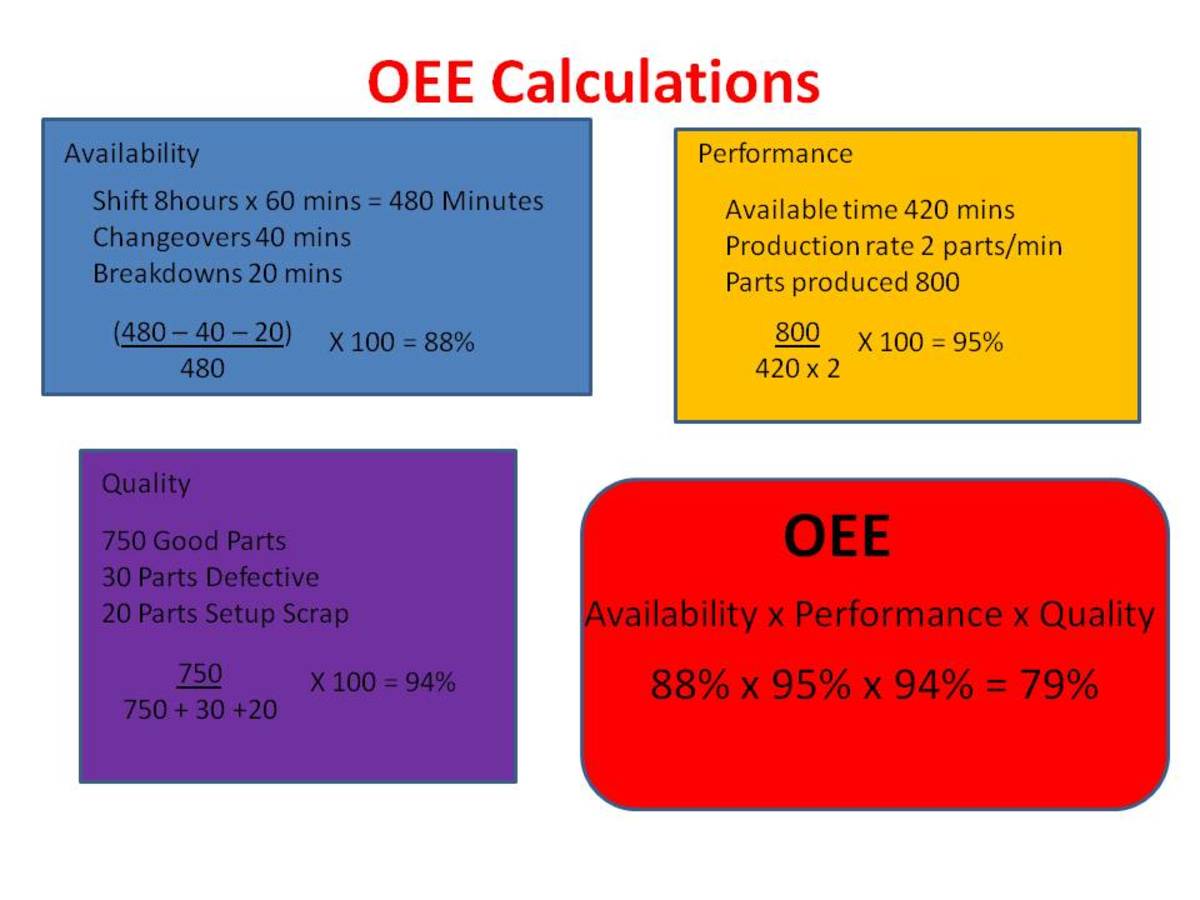

Calculating Overall Effective Equipment Oee Clearmark It is calculated as: oee = availability × performance × quality. if the equations for availability, performance, and quality are substituted in the above and reduced to their simplest terms, the result is: oee = (good count × ideal cycle time) planned production time. this is the “simplest” oee calculation described earlier. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. an oee score of 100% represents perfect production: manufacturing only good parts, as fast as possible, with no downtime. oee is useful as both a benchmark and a baseline:.

How To Calculate Your Overall Equipment Effectiveness Oee Toughnickel Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. it provides insights into how well equipment is used and how efficiently it operates in producing goods or delivering services. the oee calculation takes into account three key factors:. Overall equipment effectiveness. overall equipment effectiveness[1] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared to its full potential, during the periods when it is scheduled to run. it identifies the percentage of manufacturing time that is truly productive. A practical definition of oee. oee is the overall equipment effectiveness of a defined production process during the defined operative period or mode in which all activities related to production, personnel and inputs are accounted for during all producing or dependent activities within a defined scheduled time or operative mode time. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. simply put – it identifies the percentage of manufacturing time that is truly productive. an oee score of 100% means you are manufacturing only good parts, as fast as possible, with no stop time.

Advantages Of Overall Equipment Effectiveness Oee A practical definition of oee. oee is the overall equipment effectiveness of a defined production process during the defined operative period or mode in which all activities related to production, personnel and inputs are accounted for during all producing or dependent activities within a defined scheduled time or operative mode time. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. simply put – it identifies the percentage of manufacturing time that is truly productive. an oee score of 100% means you are manufacturing only good parts, as fast as possible, with no stop time. The overall equipment effectiveness (oee) for this widget factory, based on the given data, is approximately 72.93%. this means that, taking into account the time the equipment was available, how well it performed, and the quality of the widgets produced, the factory was operating at about 72.93% of its ideal capacity. Oee, or overall equipment effectiveness, is a term used widely in the manufacturing industry. oee is regarded as a valuable component of manufacturing best practice guidelines. it relates to the proportion of time that is truly productive. the higher the oee score, the higher the production time. boosting productivity is beneficial for.

Overall Equipment Effectiveness Oee Ten Engineering S R L The overall equipment effectiveness (oee) for this widget factory, based on the given data, is approximately 72.93%. this means that, taking into account the time the equipment was available, how well it performed, and the quality of the widgets produced, the factory was operating at about 72.93% of its ideal capacity. Oee, or overall equipment effectiveness, is a term used widely in the manufacturing industry. oee is regarded as a valuable component of manufacturing best practice guidelines. it relates to the proportion of time that is truly productive. the higher the oee score, the higher the production time. boosting productivity is beneficial for.

Comments are closed.