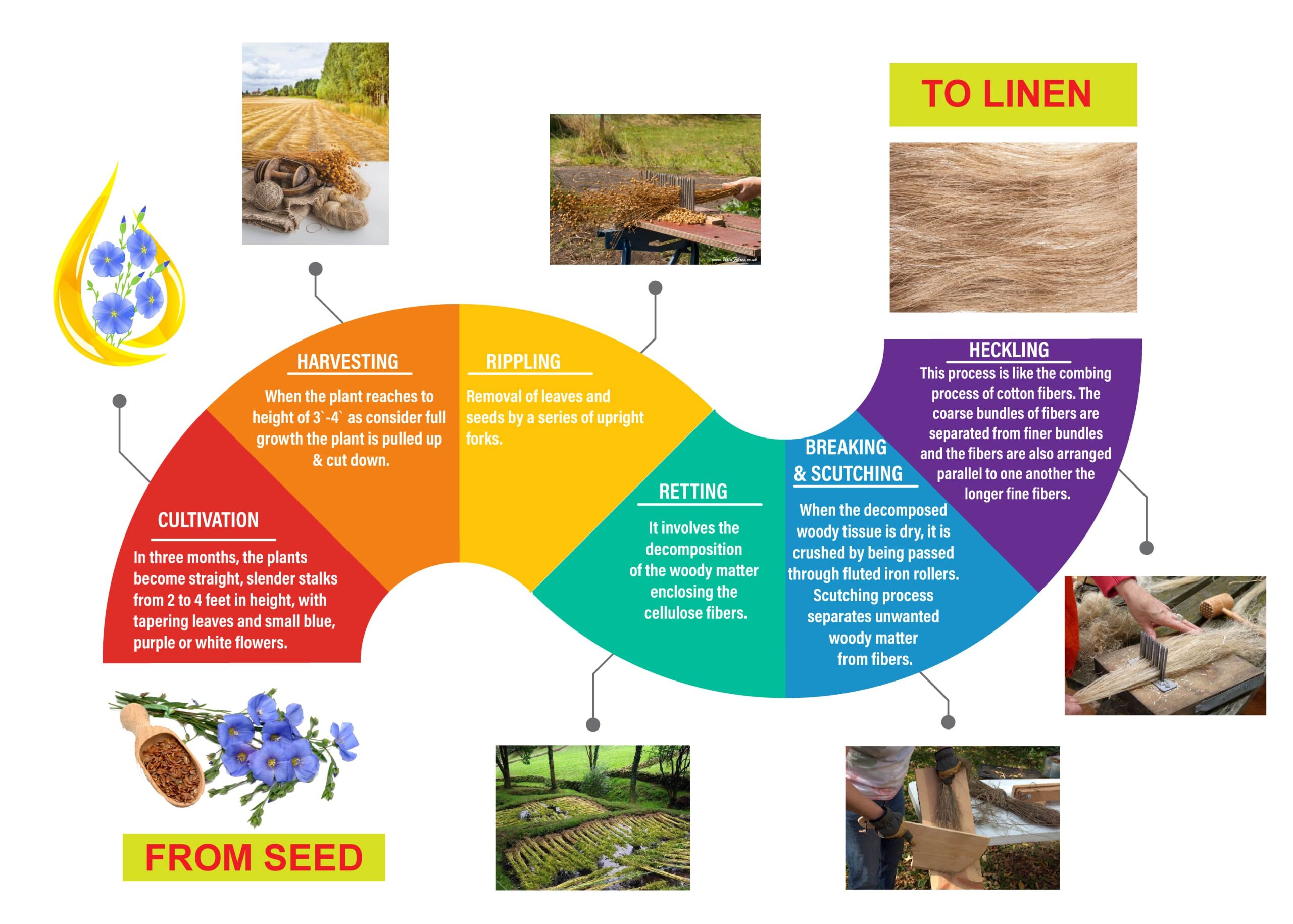

Production Process Information Of Flax Fibers To Linen Yarns

Production Flowchart Of Linen Or Flax Fibre Textile Apex 3) rippling flax – rippling is a process in flax production where the upper part of flax bundles is combed through coarse combs to remove seeds. this step separates the seeds from the fibres, a crucial preparation for further stages in the transformation of flax into linen. 4) retting the stalks – once harvested, the flax stalks undergo a. Linen flax fibers vary in length from about 25 to 150 mm (1 to 6 inches) and average 12–16 micrometers in diameter. there are two varieties: shorter tow fibers used for coarser fabrics and longer line fibers used for finer fabrics. flax fibers can usually be identified by their “nodes” which add to the flexibility and texture of the fabric.

Flax Fibre Production Process Properties And End Uses A To Z 4. rippling flax. first, the upper part of the flax bundles are drawn through coarse combs to remove seed in a process called rippling. after the seeds are removed, it is necessary to separate the long, silky inner fibers which constitute the end product from the straw and inner pitch. 5. Once the plants have matured, they are harvested and the fibers are extracted. this is followed by a process called retting, where the fibers are soaked in water to break down the plant’s outer layer. after retting, the fibers are spun into yarn and woven into fabric. today, linen production has a significant economic impact, with many. The flax seeds are sown in early spring and after approximately 100 days, the plants are about one metre tall. they then bloom at the end of june. the plants are harvested, roots and all, and placed in neat rows in the fields. after harvest, retting takes place. the linen fibres slowly soften, making it possible to extract them from the outer husk. The process of transforming flax fibers into linen cloth has been practiced for centuries and is a sustainable way to create clothing and household textiles. growing flax can be a rewarding experience, from nurturing the delicate blueish purple flowers to harvesting and processing the fibers to create your own linen fabric.

Flax Fiber Yarn Linen Produced From The Bast Of The Flax Plant The flax seeds are sown in early spring and after approximately 100 days, the plants are about one metre tall. they then bloom at the end of june. the plants are harvested, roots and all, and placed in neat rows in the fields. after harvest, retting takes place. the linen fibres slowly soften, making it possible to extract them from the outer husk. The process of transforming flax fibers into linen cloth has been practiced for centuries and is a sustainable way to create clothing and household textiles. growing flax can be a rewarding experience, from nurturing the delicate blueish purple flowers to harvesting and processing the fibers to create your own linen fabric. Flax (linum usitatissimum) is a plant that’s grown in cooler places around the world. people plant its seeds in the early part of the year, and it takes about 100 days to grow. renowned for its slender stems, it is primarily grown for its valuable fibers and seeds, contributing to the production of linen textiles and nutrient rich flaxseed oil. Linen fabric production & dyeing: q&a. july 20, 2023. while dyeing textiles has a rich history spanning millennia, the environmental consciousness of modern times has put sustainability at the forefront of our choices. in this regard, linen stands out as one of the most eco friendly fabrics available today. from its inception as fibers derived.

Production Process Information Of Flax Fibers To Linen Yarns Flax (linum usitatissimum) is a plant that’s grown in cooler places around the world. people plant its seeds in the early part of the year, and it takes about 100 days to grow. renowned for its slender stems, it is primarily grown for its valuable fibers and seeds, contributing to the production of linen textiles and nutrient rich flaxseed oil. Linen fabric production & dyeing: q&a. july 20, 2023. while dyeing textiles has a rich history spanning millennia, the environmental consciousness of modern times has put sustainability at the forefront of our choices. in this regard, linen stands out as one of the most eco friendly fabrics available today. from its inception as fibers derived.

Production Process Information Of Flax Fibers To Linen Yarns

Comments are closed.