Reverse Return Piping Diagram Water Cooling

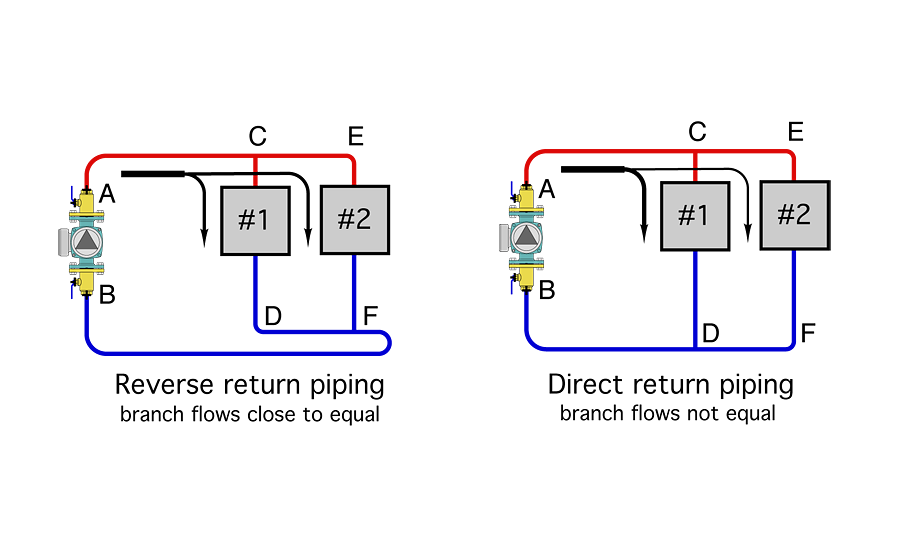

When And How To Use Reverse Return Piping 2016 11 16 Plumbing And Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. it also shows a direct return piping layout for comparison. the reverse return arrangement has the potential to create approximately equal flow resistance through each branch and produce flows that are closer to equal. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head of the pump. this requires the total head of the pump in the reverse return system to be higher than the direct return system (147.9 feet vs. 129.7 feet in this example).

Reverse Return Piping Diagram Water Heaters If reverse return piping setup was adopted as shown in the above diagram, tank 1 will be the first to receive cold water supply (cws) but the last to provide hot water supply (hws). the result is all three tanks will be supplying approximately the same amount of hot water. Refrigerant diagrams. closed loop systems can be further classified as direct return or reverse return. the direct return system allows piping to be run in the most direct path to optimize piping costs. the reverse return system is piped so that the length of the water circuit through the supply and return piping to each fan coil or air handler. 01 when and how to use reverse return piping. in many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. the physics necessary for this are simple: if the flow resistance of each piping path from a common source point to a common return point is the same, the. Efficiency & longevity: this setup ensures balanced water flow and usage between both heaters, enhancing system efficiency and extending the lifespan of your heaters. adaptability: reverse return can be modified to incorporate additional features like a recirculating line or a mixing valve, providing flexibility for diverse scenarios.

Comments are closed.