Schematic Diagram Of Cooling Tower

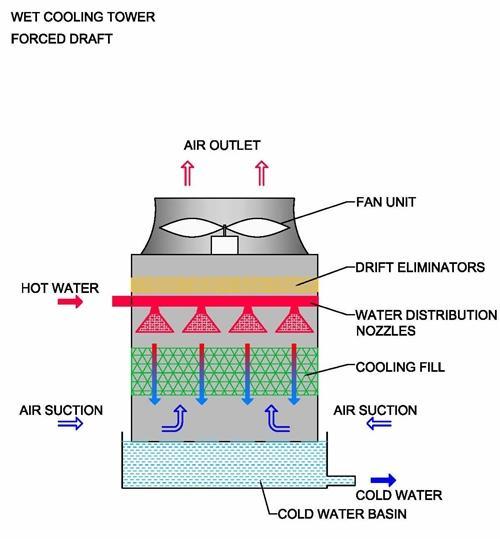

Cooling Tower Diagram A Go To Guide To Learn About Their Function Cooling tower | piping layout and diagrams. to allow the cooling towers to operate correctly, in line with the design and efficiently, various systems will need to be connected to allow them to work. depending upon how the towers are installed will mean different configurations would be required. the pipework that is commonly connected to the. A cooling tower flow diagram helps visualise the complex system of the tower and its components. the diagram illustrates the flow of water and air through the tower, as well as the different stages of the cooling process. the cooling tower flow diagram typically begins with the entry of hot water from the industrial process into the tower.

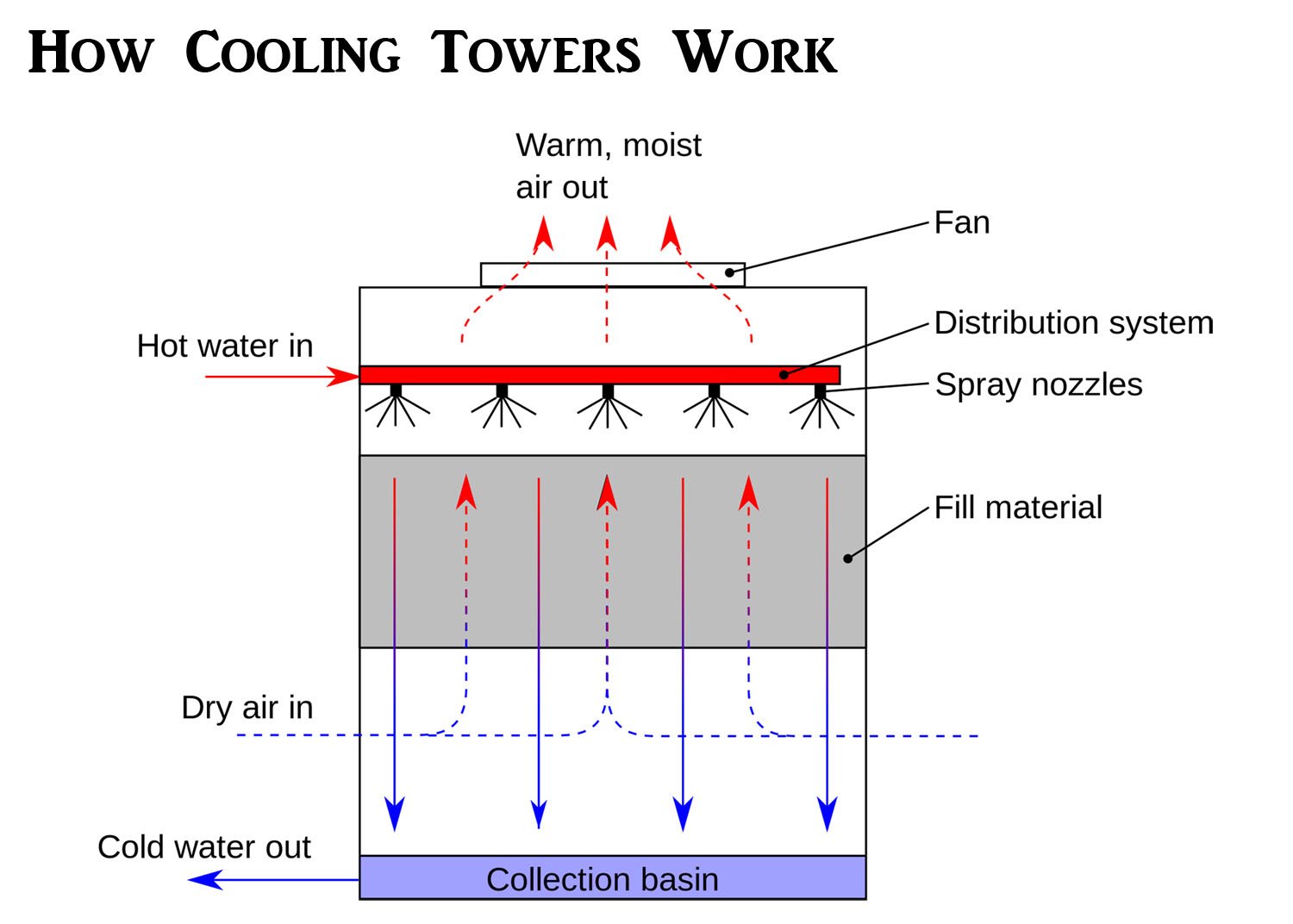

How Cooling Towers Work W Diagram Pictures Principles 2018 The water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical "cooling tower fan". when the air and water come into the contact, a little amount of water dissipates, producing a cooling operation. and again the cold water is pumped back to the machine that incorporates heat or the. Counterflow cooling tower diagram difference between crossflow and counterflow cooling towers: in counterflow cooling tower system processes, the air vertically flows upwards, counter to the water flow in the fill media. due to the air flowing vertically, it's not possible to use the basin's gravity flow like in crossflow towers. Closed circuit towers. in these cooling towers, it passes the working fluid through heat exchangers upon which the clean water is sprayed and a fan induced draft applied. the performance of the closed circuit cooling tower is near to the wet cooling towers. wet cooling towers. the wet cooling towers operates on the principle of evaporative cooling. The cooling tower circuit differs slightly from the basic “open” circuit in that the discharge piping is connected directly to a distribution basin. some towers are furnished with a distribution manifold with nozzles which require additional pressure. figure 3 typical “open” tower piping.

Schematic Drawing Showing The Basic Components Of A Cooling Tower Closed circuit towers. in these cooling towers, it passes the working fluid through heat exchangers upon which the clean water is sprayed and a fan induced draft applied. the performance of the closed circuit cooling tower is near to the wet cooling towers. wet cooling towers. the wet cooling towers operates on the principle of evaporative cooling. The cooling tower circuit differs slightly from the basic “open” circuit in that the discharge piping is connected directly to a distribution basin. some towers are furnished with a distribution manifold with nozzles which require additional pressure. figure 3 typical “open” tower piping. The two diagrams below show the design differences between crossflow, on the right, and counterflow, on the left, of natural draft cooling towers. the tower can cool up to 480,000 gallons of water per minute. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser.

Schematic Diagram Of Cooling Tower The two diagrams below show the design differences between crossflow, on the right, and counterflow, on the left, of natural draft cooling towers. the tower can cool up to 480,000 gallons of water per minute. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser.

Comments are closed.