Smart Goals Definition Method Benefits Explained Lean Manufacturing Tools

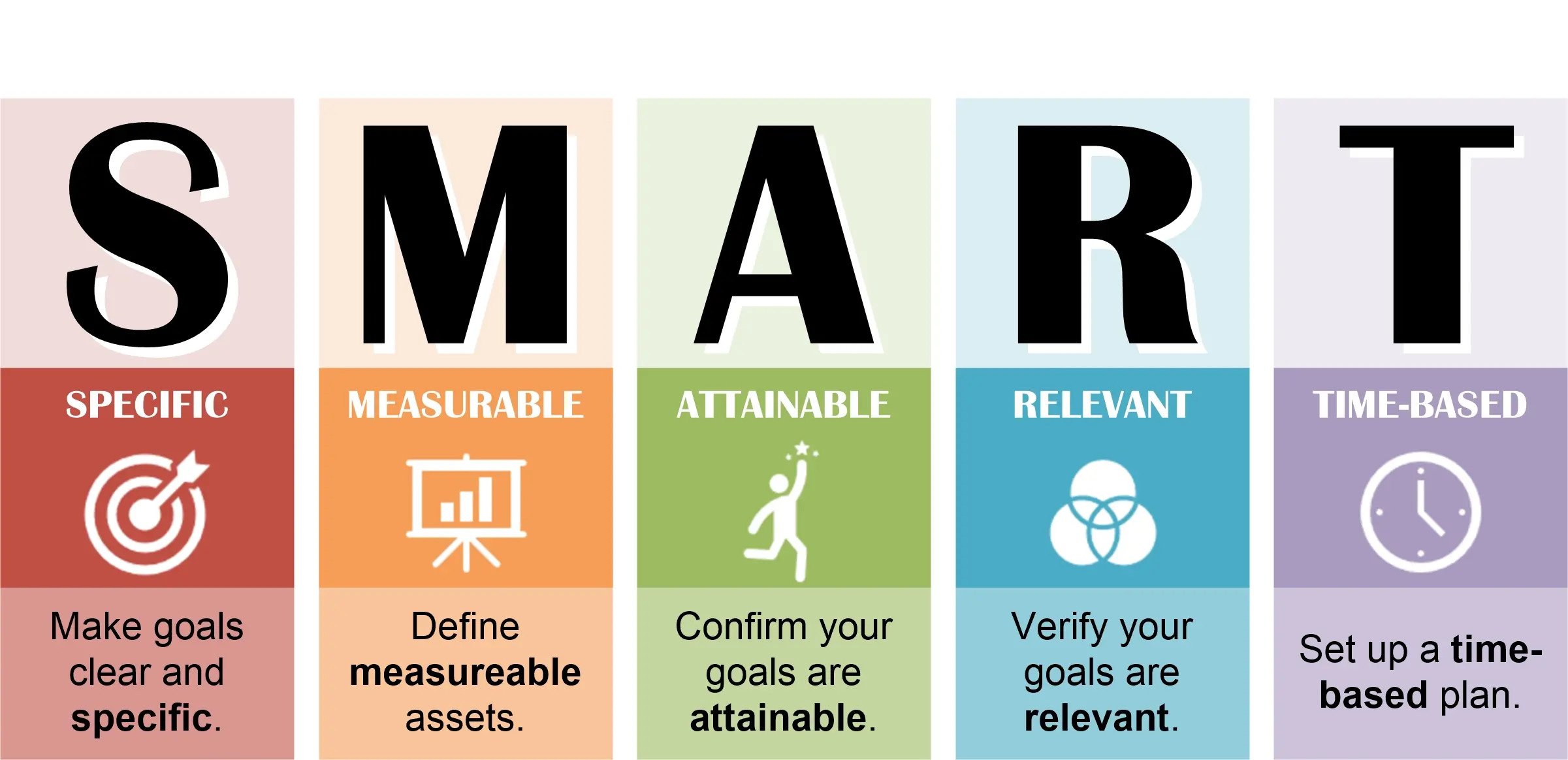

Smart Goals Definition Method Benefits Explained Lean This lean six sigma course lecture covers a short discussion on smart goals definition, method, benefits explained (lean manufacturing tools)subscribe to @. Smart is an acronym to describe a goal setting and communication standard which has the following characteristics : a goal to be achieved must be: specific: be clearly set out in a specific manner. refer to actual facts and concrete figures. measurable: the results or goal must be able to be measured in units or in any other exact way.

Lean Manufacturing Tools While the reduction of waste is the number one goal of lean manufacturing, there are other advantages to utilizing a lean system: increase productivity. deliver better quality. lower operating costs. utilizing lean manufacturing tools in your production process can lead to many secondary benefits as well. The kaizen method generally involves 5 primary steps: identify the problem area that will be given focus. utilize videotape to analyze the current method. test and evaluate improvement tactics. implement improvements. analyze results and present them to upper management for feedback. The best way to use lean tools is to understand that they are means to enact the principles of lean philosophy, not a replacement for a lean philosophy or a lean culture. some lean practitioners emphasize nine lean principles and techniques: cut out waste. improve continuously. respect the role of people. Benefits of lean manufacturing. lean manufacturing has gained such popularity for a reason—it works. more specifically, it works to reduce inventory overhead, reduce overtime, postpone capital investment, increase throughput, and reduce lead times by an average 99%. lean manufacturing also results in improved customer service, higher quality.

Lean Manufacturing 101 The best way to use lean tools is to understand that they are means to enact the principles of lean philosophy, not a replacement for a lean philosophy or a lean culture. some lean practitioners emphasize nine lean principles and techniques: cut out waste. improve continuously. respect the role of people. Benefits of lean manufacturing. lean manufacturing has gained such popularity for a reason—it works. more specifically, it works to reduce inventory overhead, reduce overtime, postpone capital investment, increase throughput, and reduce lead times by an average 99%. lean manufacturing also results in improved customer service, higher quality. Introduction to lean manufacturing. lean manufacturing is a management approach derived from the toyota production system, devised in japan after world war ii. it aims to maximize value for the customer by eliminating waste, meaning it seeks to optimize processes by using fewer resources and focusing on what is essential to meet customer demands. Lean manufacturing tools. besides the techniques above, there are several tools that can help you in implementing lean manufacturing ideals, including: kanban board. a kanban board is a simple yet handy lean manufacturing tool. in its essence, it’s a board divided into several sections. each section represents a production phase in your plant.

Smart Goals Definition And Examples Introduction to lean manufacturing. lean manufacturing is a management approach derived from the toyota production system, devised in japan after world war ii. it aims to maximize value for the customer by eliminating waste, meaning it seeks to optimize processes by using fewer resources and focusing on what is essential to meet customer demands. Lean manufacturing tools. besides the techniques above, there are several tools that can help you in implementing lean manufacturing ideals, including: kanban board. a kanban board is a simple yet handy lean manufacturing tool. in its essence, it’s a board divided into several sections. each section represents a production phase in your plant.

Comments are closed.