Textile Dyeing Process Flowchart Of Knit Fabric Dyeing Process Yout

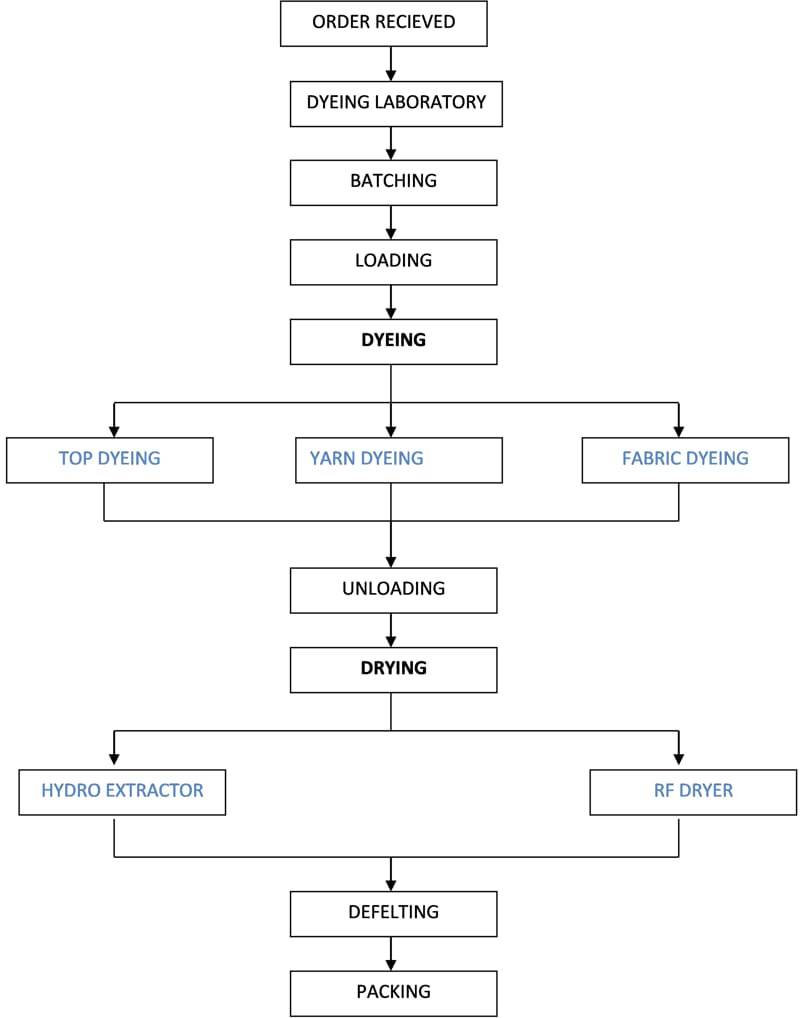

Dyeing Flow Chart вђ Practical Textile The process is given below. bleaching: remove the natural color. enzyme: remove protruding fiber from the surface of the fabric. dyeing: a coloring substance applies here to the core of the fiber. aftertreatment: loose dyes removes by soaping here. unload: unload the fabric and delivery it to the finishing department. Knit dyeing refers to the process of applying color to knitted fabrics or garments. it is a method of adding or changing the color of yarn or fabric that has already been knitted. the process involves immersing the knitted material in a dye solution to achieve the desired color. knit dyeing can be performed on various types of knit fabrics.

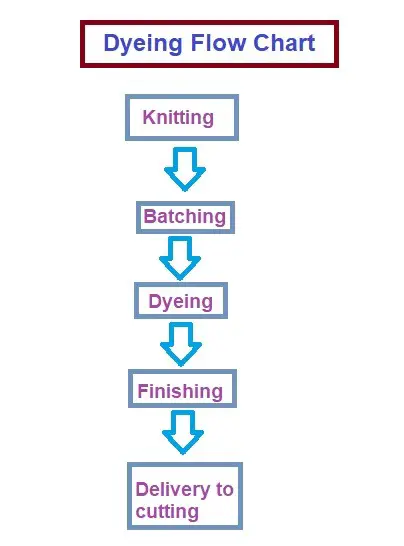

Textile Dyeing Process Flowchart Of Knit Fabric Dyeing This process is done in 3 steps: 1)soaping: in this step, the fabric is soaped with the help of detergent soaping agent as a result of which the unfixed dyes are removed from the fabric surface. in this step the soaping agent is injected and then the temperature is raised at 90°c for 10mins and than drain and wash. Definition of dyeing process flowchart of knit fabric dyeing processdyeing is the process of application of various dyes and chemicals to the fiber, fabric,. Process flow chart of knit dyeing. march 10, 2015 by textile flowchart. knit dyeing: knit dyeing is a technique of dyeing knitted fabrics. the dyeing of knitted fabrics occurs in the exhaust method or in batch wise process. the knit dyeing process is near similar to the yarn dyeing process but there is some difference in quality measurement. Dryer. conclusion: knit fabric finishing is an important part of the textile manufacturing process. finishing process plays a crucial role in achieving desired characteristics and ensuring high quality knit fabrics. by proper finishing of knit fabrics can be made to be soft, durable, and resistant to shrinking, wrinkling, and fading.

Flow Chart Of Wet Processing Of Fabric In The Fabric Dyeing Unit Process flow chart of knit dyeing. march 10, 2015 by textile flowchart. knit dyeing: knit dyeing is a technique of dyeing knitted fabrics. the dyeing of knitted fabrics occurs in the exhaust method or in batch wise process. the knit dyeing process is near similar to the yarn dyeing process but there is some difference in quality measurement. Dryer. conclusion: knit fabric finishing is an important part of the textile manufacturing process. finishing process plays a crucial role in achieving desired characteristics and ensuring high quality knit fabrics. by proper finishing of knit fabrics can be made to be soft, durable, and resistant to shrinking, wrinkling, and fading. Cotton is the most popular useable fiber in the world. here we discuss the 100% cotton fabric knitting dyeing process, dyeing process with reactive dye, finishing process, and flow chart of knitting, dyeing, and finishing process with complete practical documentation which i did recently. dyeing cotton fabric at home is also a common practice in. Cold wash at 40 ºc for 5 10 minutes. ↓. hot wash at 95 ºc for 5 10 minutes. ↓. the required amount of water was loaded. ↓. acetic acid was added. ↓. the temperature increased at 80 ºc for 15 20 minutes.

Yarn To Fabric Manufacturing Page 9 Of 10 Textile School Cotton is the most popular useable fiber in the world. here we discuss the 100% cotton fabric knitting dyeing process, dyeing process with reactive dye, finishing process, and flow chart of knitting, dyeing, and finishing process with complete practical documentation which i did recently. dyeing cotton fabric at home is also a common practice in. Cold wash at 40 ºc for 5 10 minutes. ↓. hot wash at 95 ºc for 5 10 minutes. ↓. the required amount of water was loaded. ↓. acetic acid was added. ↓. the temperature increased at 80 ºc for 15 20 minutes.

Comments are closed.