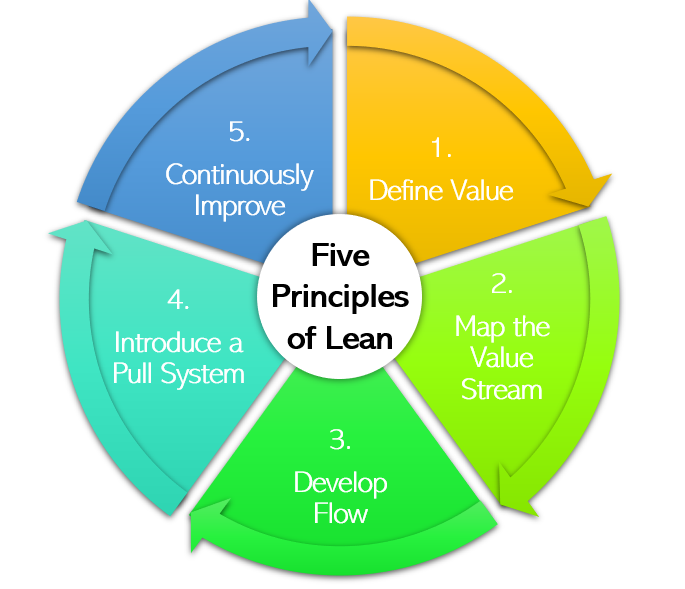

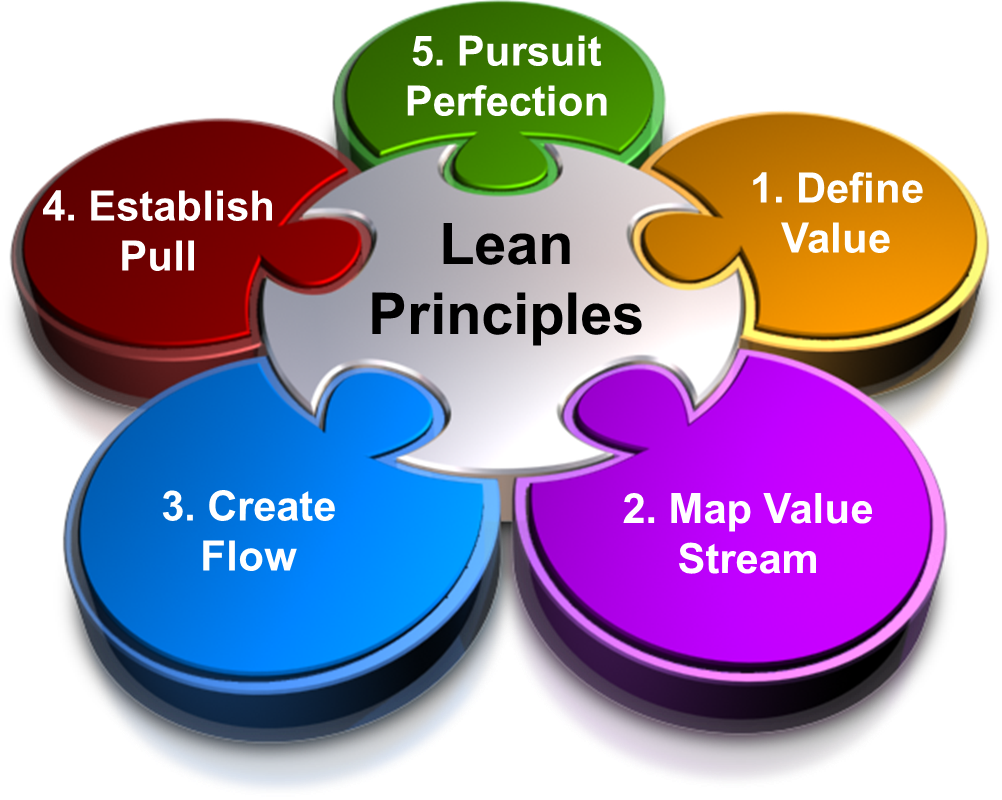

The Five Principles Of Lean

The Five Principles Of Lean Learn how to apply the five principles of lean manufacturing to improve workplace efficiency and customer value. the principles are defining value, mapping the value stream, creating flow, using a pull system, and pursuing perfection. Learn how lean principles can help you eliminate waste and improve your business processes. the five principles are value, value stream, flow, pull, and perfection.

The 5 Principles Of Lean And How To Apply Them Lean Outside The Box The lean enterprise institute (lei), founded by james p. womack and daniel t. jones in 1997, is considered the go to resource for lean wisdom, training, and seminars. according to womack and jones, there are five key lean principles: value, value stream, flow, pull, and perfection. 1. value. value is always defined by the customer’s needs for. The lean principles originated from the toyota production system (tps), these principles are clear sets of guidelines and techniques aimed at improving processes, minimizing waste, and therefore resulting in an overall increase in customer value. the five principles of lean are: 1. to identify value, 2. mapping the value stream, 3. Website. save my name, email, and website in this browser for the next time i comment. this site uses akismet to reduce spam. . the five principles of lean: value, value stream, flow, pull, and continuous improvement help eliminate waste and improve process efficiency. Learn the key elements of lean management and how to apply them in any industry to eliminate waste and improve efficiency. the five principles of lean are define value, map the value stream, create flow, establish pull, and pursue perfection.

The Principles Of Lean Think Different Website. save my name, email, and website in this browser for the next time i comment. this site uses akismet to reduce spam. . the five principles of lean: value, value stream, flow, pull, and continuous improvement help eliminate waste and improve process efficiency. Learn the key elements of lean management and how to apply them in any industry to eliminate waste and improve efficiency. the five principles of lean are define value, map the value stream, create flow, establish pull, and pursue perfection. Waiting. non utilized talent. transportation. inventory. motion and extra processing. there is also the concept of lean enterprise, which expands the ideology to the entire value stream or supply chain. lean manufacturing and enterprise ideally work together to reach the fullest expression of the lean philosophy. The five lean principles, namely value, value stream, flow, pull, and perfection, serve as a guiding compass, propelling project managers towards substantial improvements in operations and output. this comprehensive guide will delve into each of these principles, providing in depth definitions, practical insights, and illustrative examples to.

Comments are closed.