Truss Girder Roof Structure Framing Diagram

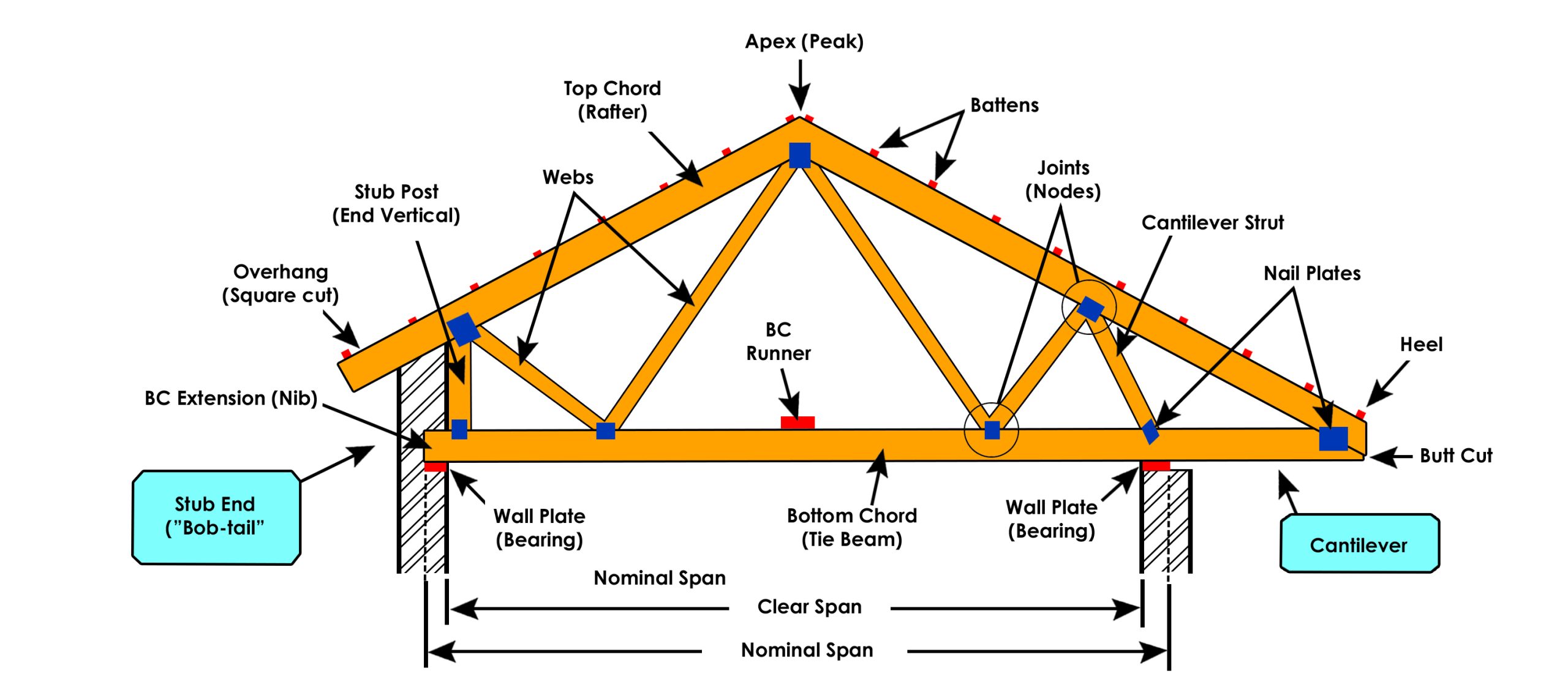

Truss Girder Roof Structure Framing Diagram 1. anatomy of a basic roof truss. roof truss parts explained. rafter: one of a series of diagonal members of the truss that meet at the apex in order to support the roof deck and its loads. underpurlin: horizontal beams supported by posts and used to support the mid span of rafters to cover longer spans. these are used in large buildings like. The truss roof is a structural roof system spanning between 2 supports and carrying loads like wind, snow and live load. compared to other trusses, the truss roof is usually inclined from the supports towards the midpoint. it consists of top chord, bottom chord, diagonals and connections. statically speaking are the top and bottom chords beams.

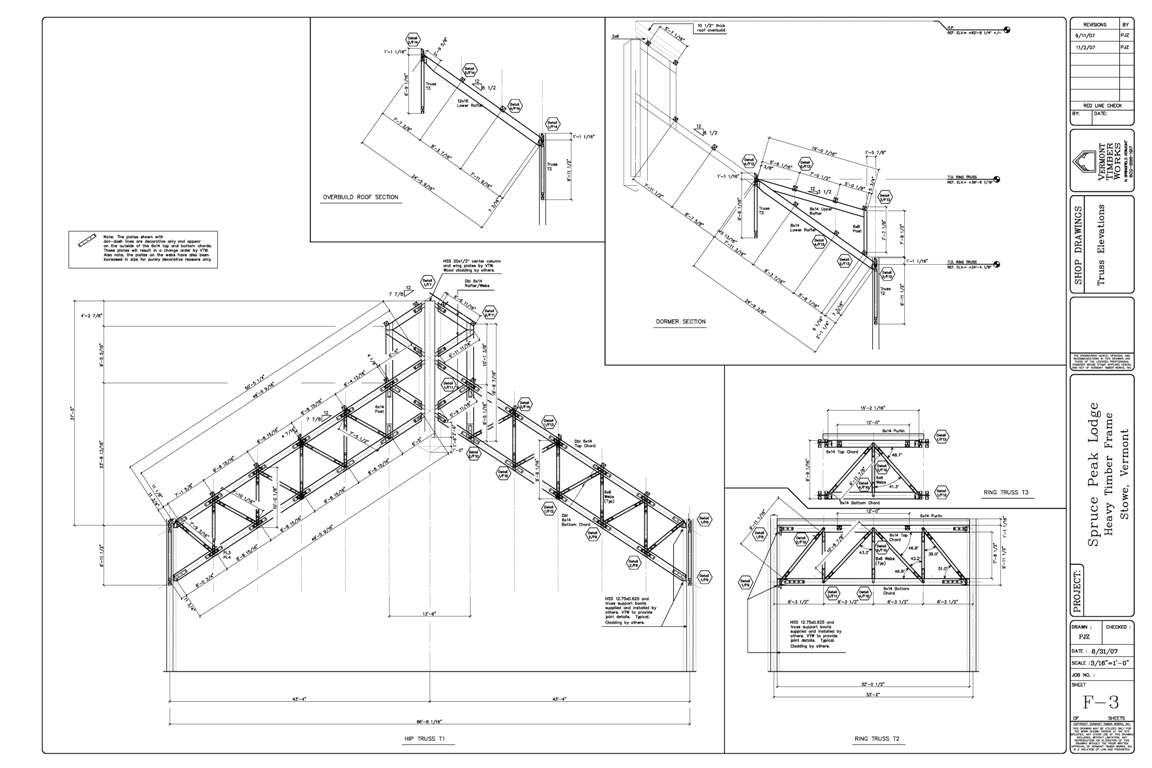

Truss Girder Roof Structure Framing Diagram Tfec 4 2020. r timber roof trussesaugust 2020 this document is intended to be used by engineers to provide guidance in designing and eva. uating timber roof truss structures. do not attempt to design a timber roof truss structure without adult supervision from a qualified professional (prefer. In this tutorial, we will design a roof truss for a garage with the following information: location: 8050 sw beaverton hillsdale hwy, portland, or 97225, usa. building length: 10.0m. building width: 7.0m. eave height: 4.0m. roof truss height: 2.0m. roof angle: 29.745°. enclosure: open building. we will be using an l shape (aisc) section for. Mitek also offers the very best in framing layout and engineering software for roof and floor trusses, as well as wall panel design. these programs provide our fabricators with fast and accurate layout and design capabilities. our engineering department is available to review and seal our customers’designs. B. triangle truss configurations. below is a detailed breakdown and, in most cases, an explanation of each type of truss. 1. studio two bearing points truss. 2. studio three bearing points. used on larger trusses and for creating a pitched ceiling or an extra vertical space. 3. coffer tray truss.

Roof Truss Elements Angles And Basics To Understand Engineering Mitek also offers the very best in framing layout and engineering software for roof and floor trusses, as well as wall panel design. these programs provide our fabricators with fast and accurate layout and design capabilities. our engineering department is available to review and seal our customers’designs. B. triangle truss configurations. below is a detailed breakdown and, in most cases, an explanation of each type of truss. 1. studio two bearing points truss. 2. studio three bearing points. used on larger trusses and for creating a pitched ceiling or an extra vertical space. 3. coffer tray truss. In this “how it works” column, structural engineer rob munach explains how trusses carry their loads and how t bracing and roof sheathing add strength. an illustration shows the compression and tension ratings of a truss that has been modeled with a combined dead, live, and snow load of 40 lb. per sq. ft. munach stresses that trusses cannot. Fix batten to stiffener with roof battens at max 1200 crs. fixed to each truss minimum 2 3.15 dia. x 75 using 1 14g type 17 screw with minimum 45mm nails at each side of splice penetration into truss top chord or equivalent. splice 70 min. 45 min. 210 min.

Girder Truss вђ Vermont Timber Works In this “how it works” column, structural engineer rob munach explains how trusses carry their loads and how t bracing and roof sheathing add strength. an illustration shows the compression and tension ratings of a truss that has been modeled with a combined dead, live, and snow load of 40 lb. per sq. ft. munach stresses that trusses cannot. Fix batten to stiffener with roof battens at max 1200 crs. fixed to each truss minimum 2 3.15 dia. x 75 using 1 14g type 17 screw with minimum 45mm nails at each side of splice penetration into truss top chord or equivalent. splice 70 min. 45 min. 210 min.

Comments are closed.