Us Motors Cooling Tower Duty Wiring Diagram

Weg W22 Cooling Tower Motor Wiring Diagram Wiring Diagram Triple rate motor connection: 2010950 : single voltage, wye connected, with partial current transformer protection: 2010964 : single voltage, wye connected, with partial current transformer protection, lightning arrestors & surge capacitors: blower : single & three phase blower connection diagrams, * thermally protected. Technical data. installation & maintenance instructions. wiring diagrams & electrical references. dimension prints. product & marketing data sheets. faqs. see ecatalog for rating specific data on standard products. print catalog pages. driver technology for variable speed applications.

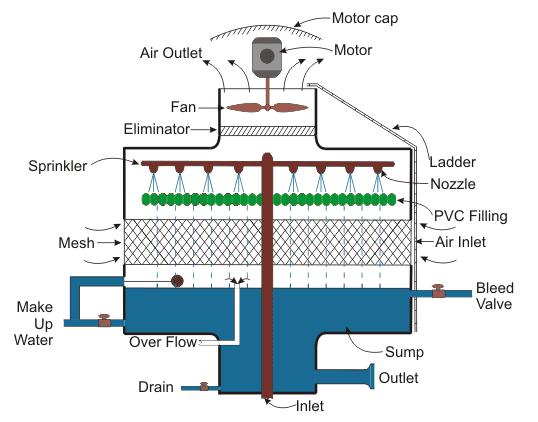

Weg W22 Cooling Tower Motor Wiring Diagram Wiring Diagram Issues. this product service manual defines warranty policy, procedures, and product service contacts for u.s. motors® brand products, which must be utilized when. carrying out product warranty repairs and replacements. product service and warranty administration for us motors® brand products are handled out of the corporate. Buy us motors (nidec) hw15v2e2 chiller cooling tower motor 15 hp, 1800 rpm, 3 ph, 190 380 230 460 v, 254t frame, tefc (totally enclosed fan cooled) enclosure, 50 60 hz, 1465 rpm 1775 rpm base, horizontal foot mount, continuous duty at motion. 2 hp 1200 rpm, 6.2 3.1 amps 230 460 volts 60 hz three phase motor; nema 184t cast iron frame keyed shaft 1 1 8" diameter x 2 3 4" service factor: 1.15, overload protection = none; rigid base mount, ball bearings, class f insulation, reversible; 1 year manufacture warranty; for use in cooling tower and evaporation cooler applications. Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. during this process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower.

Wiring Diagram For Cooling Tower Motors 2 hp 1200 rpm, 6.2 3.1 amps 230 460 volts 60 hz three phase motor; nema 184t cast iron frame keyed shaft 1 1 8" diameter x 2 3 4" service factor: 1.15, overload protection = none; rigid base mount, ball bearings, class f insulation, reversible; 1 year manufacture warranty; for use in cooling tower and evaporation cooler applications. Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. during this process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower. Chiller cooling tower motor 20 hp, 1800 rpm, 3 ph, 190 380 230 460 v, 256t frame, teao (totally enclosed air over) enclosure, 50 60 hz, horizontal foot mount, continuous duty. mi item # 05655622. mfr # hvw20v2e8. availability: factory order. this product requires a quote request. To operate in the harsh cooling tower environment, resulting in less motor failures, downtime, and replacements. here at bac, we believe in our motors so much that we stand by them with a 7 year warranty when the motor space heater is wired according to the motor wiring diagram. energy efficient with flexible installation:.

Diagram Wiring Diagram For Cooling Tower Motors Mydiagram Onlin Chiller cooling tower motor 20 hp, 1800 rpm, 3 ph, 190 380 230 460 v, 256t frame, teao (totally enclosed air over) enclosure, 50 60 hz, horizontal foot mount, continuous duty. mi item # 05655622. mfr # hvw20v2e8. availability: factory order. this product requires a quote request. To operate in the harsh cooling tower environment, resulting in less motor failures, downtime, and replacements. here at bac, we believe in our motors so much that we stand by them with a 7 year warranty when the motor space heater is wired according to the motor wiring diagram. energy efficient with flexible installation:.

Comments are closed.