Yarn To Fabric Manufacturing Page 9 Of 10 Textile School

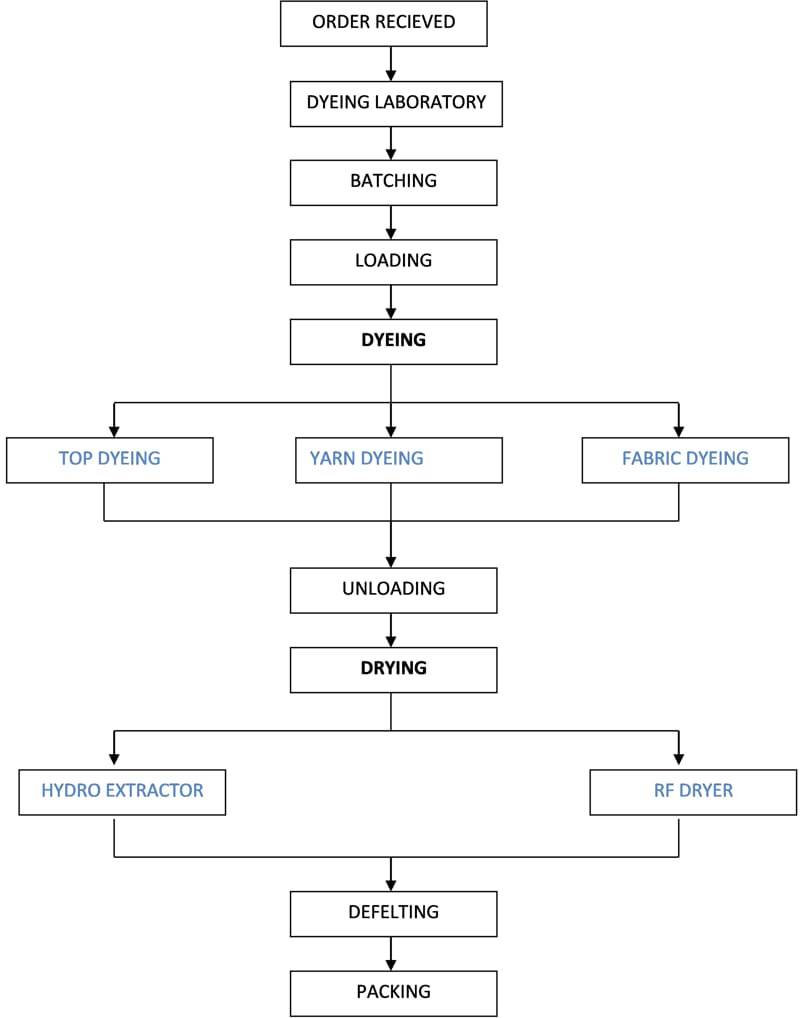

Yarn To Fabric Manufacturing Page 9 Of 10 Textile School Dyeing is the process of adding color to textile products like fibers, yarns, and fabrics. dyeing is normally done in a special solution containing dyes and particular chemical material. after dyeing, dye molecules have an uncut chemical bond with fiber molecules. temperature and time control are two key factors in dyeing. The purpose of producing doubled yarns is to improve yarn uniformity and increase strength. this is also an essential process to produce balanced yarn. it is a two stage process: doubling–thisprocessiscalled is doubling. twisting – z twist is given to the yarn while winding it on the final cone. figure 2.9: assembly winder.

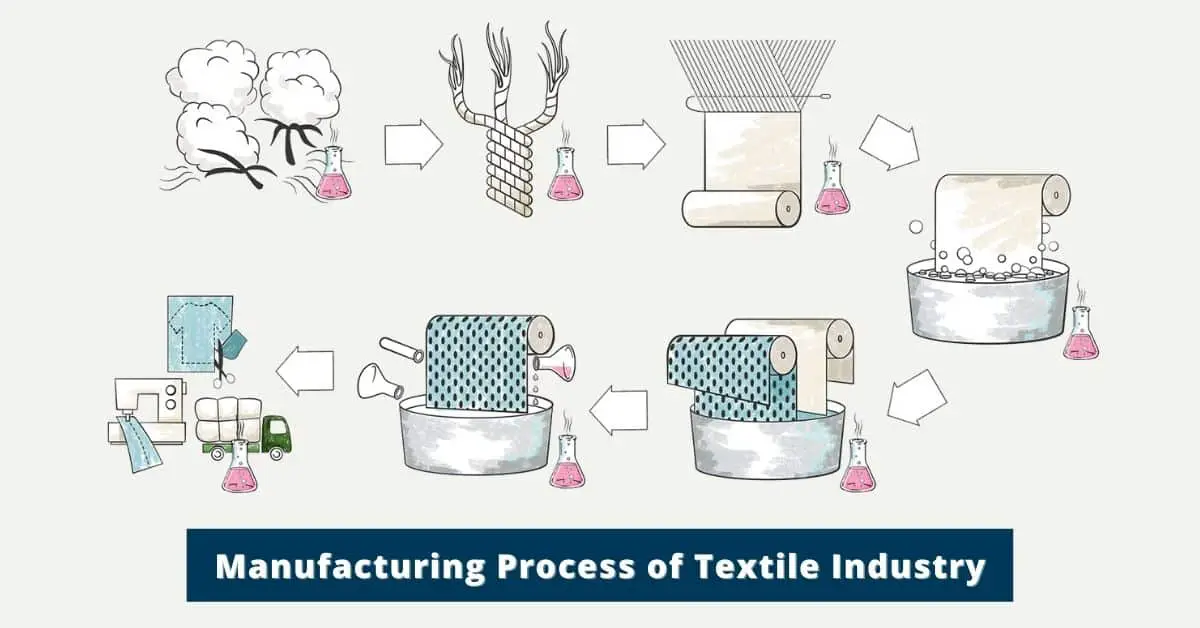

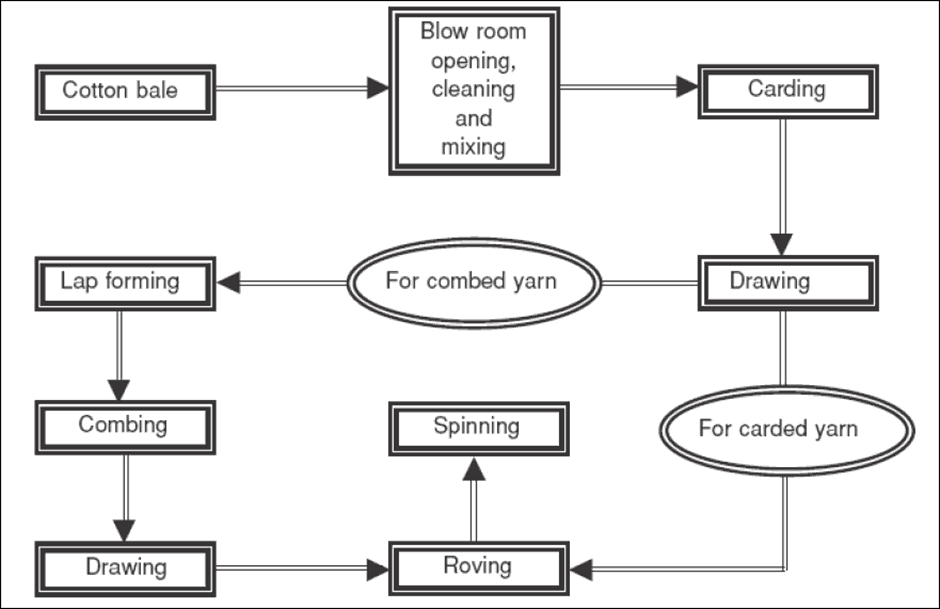

Textile Yarn Manufacturing Process At Rachael Coleman Blog Weaving is the production of fabric by interlacing two sets of yarns so that they cross each other, normally at right angles, usually accomplished with a hand or power operated loom. in weaving, lengthwise yarns are called warp; crosswise yarns are called weft, or filling. most woven fabrics are made with their outer edges finished in a manner. Textile manufacturing processes: textile industry encompasses variety of manufacturing processes that are adding value in the fiber. these processes may range over the yarn making through the garment stitching, fabric embossing, and all other composite production. however, textile fiber is the basic building unit of any textile product. Here’s a step by step guide to the woven fabric manufacturing process: step 1: spinning the yarn. the first step in the woven fabric procedure is to spin the yarn. this is done by taking the raw fibers, such as cotton, wool, or silk, and twisting them together to form a continuous strand. this strand is then wound onto a spindle, creating a yarn. Yarn is defined as a linear assemblage of the fibers twisted together. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. the process of making the yarn from a textile fiber is called spinning.

Yarn To Fabric Manufacturing Textile School Here’s a step by step guide to the woven fabric manufacturing process: step 1: spinning the yarn. the first step in the woven fabric procedure is to spin the yarn. this is done by taking the raw fibers, such as cotton, wool, or silk, and twisting them together to form a continuous strand. this strand is then wound onto a spindle, creating a yarn. Yarn is defined as a linear assemblage of the fibers twisted together. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. the process of making the yarn from a textile fiber is called spinning. Textile manufacturing. textile manufacturing or textile engineering is a major industry. it is largely based on the conversion of fibre into yarn, then yarn into fabric. these are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. The textile manufacturing processes in the global textile industry are producing the textile yarn, fiber, fabric, and finished products including apparels. the global textile industry associated with the apparel and non apparel products is expected to exceed usd 1000 billion in the next couple of years [5].

Yarn Formation Techniques Textile School Textile manufacturing. textile manufacturing or textile engineering is a major industry. it is largely based on the conversion of fibre into yarn, then yarn into fabric. these are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. The textile manufacturing processes in the global textile industry are producing the textile yarn, fiber, fabric, and finished products including apparels. the global textile industry associated with the apparel and non apparel products is expected to exceed usd 1000 billion in the next couple of years [5].

Comments are closed.